Description

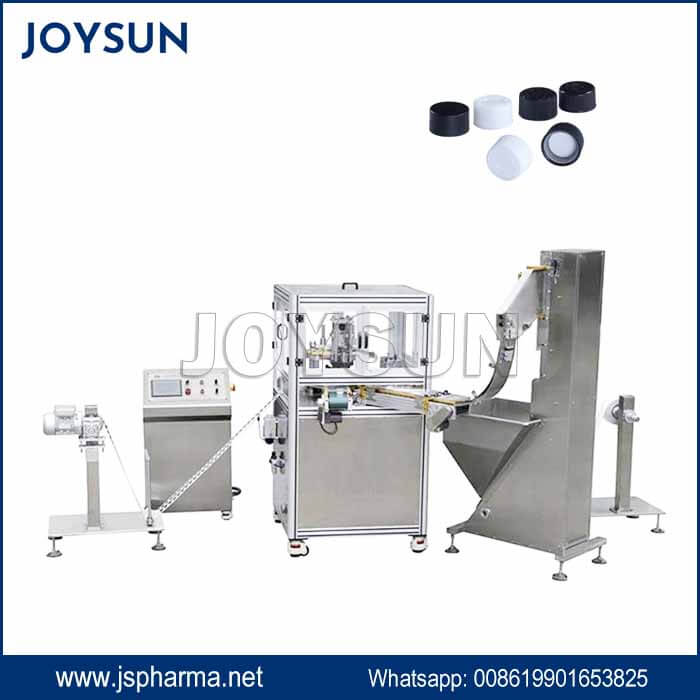

Cap Liner Insertion Machine for Sales

What is a Cap Liner Insertion Machine?

The cap liner insertion machine is an ideal equipment to automatically put cap lining material into caps. Or assemble two pieces of caps together (outer cap& inner cap). Using the machine to replace manual labor to improve working efficiency and using the machine to finish jobs that are impossible by manual work. It is mostly required by cap manufacturers and end-users whose demand is big. Whether the need to insert pre-cut round lining material or a roll-format (not pre-cut material) can be solved by different models of cap insertion machines.

For a project of very small or very big cap lining project, much can be done upon project budget and scale, options and customization is available for further discussion. For example, buyers can choose pre-cutting lining material or roll form lining material; the buyer can choose to use cold glue or hot melting glue to stick liner with caps. Due to our knowledge of cap liner insertion machines, we are capable of considering the whole process.

Cap Liner Inserter Machine Characteristics

1. Automatic cap liner machine has replaced manual work, which substantially raises the work efficiency.

2. High accuracy, high speed, and high efficiency; So that to reduce manual labor to reduce contamination and increase safety and more sanitary.

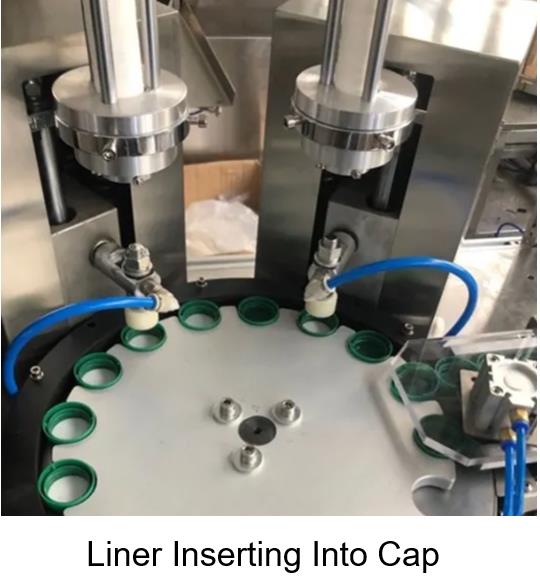

3. The machine adopts a rotary turntable with cut sizes to convey caps. So that the cap can be fit into each hole precisely. The lining material is sucked up via vacuum, and insert into the cap in a vertical downward action.

4. The replacement is a rotary turntable, lining material cylinder, and vacuum port can be easily done. Therefore the machine can fit caps of different sizes.

5. The cap sorting/cap unscrambling function can reject caps with mouth downwards. Convey them back to the cap bucket for re-sorting. Thus to ensure all caps transmit onto the conveyor belt with mouth upward, to speed up the liner insertion process.

6. Adopts touch screen and PLC control to allow various settings.

7. At the discharge stage, automatic detection of finished caps is installed to sift out disqualified caps (wrong insertion or non-insertion).

8. when there is a shortage of cap or lining material, the machine should stop for safety protection.

9. The machine can automatically count the number of caps, so it can stop when the quantity reaches pre-set input value via the touch screen. Increasing subsequent work efficiency greatly.

10. The machine is in strict accordance with national GMP standards and technological requirements. It can avoid secondary pollution of materials and omit the sterilization process, especially suitable for occasions with strict sanitary requirements.

How to select the right model to start your projects?

1. Determine the cap-size or a cap-range, one machine can work with more than one size.

2. Decide the cap shape, regular, CRC, or cone tip and etc.

3. Calculate the machine output per hour is needed.

4. Be clear about the function is needed: inserting the liner into a cap, assembling two pieces cap together, using pre-cut lining material, using roll format lining material.

5. Machine with touch screen, PLC control, or regular, with a cover or not.

Cap Liner Inserter Machine Parameter