Description

Plastic Ampoule Liquid Filling and Sealing Machine

Monodose liquid Filler/Single-Dose liquid Filler

Plastic Ampoule Filling and Sealing Machine Brief Introduction

The plastic ampoule liquid filler can do the below liquid filling and sealing package formats. The machine mainly uses PVC/PE composite film to form into desired plastic ampule shapes and sizes; filling liquid products from top and then top sealing the container; conveying to the packing process. Filling capacity: 1-50ml; special requirement needs customizing. See below different plastic ampoule samples.

Plastic Ampoule Filler Application:

This plastic ampoule filler is widely used in different industries and areas:

♠ Fill and seal oil products: oil that is with certain fluidity and not becomes solid during filling is suitable to be filled on our liquid filling and sealing machine including coconut oil, vegetable oil, olive oil, peanut oil, sunflower seed oil, argan oil, rice bran oil, avocado oil, palm oil, canola oil, tea oil, macadamia oil and etc.

♠ Fill and seal chemicals product: for some portable chemicals of special purposes like pesticide, liquid fertilizer, agricultural chemical, herbicide, fungicide, insecticide, previous energy, seaweed organic extract,/liquid, weed killer and plant growth stimulator. disinfectant fluid, sanitizer, disinfector, thimerosal liquid, alcohol sterilizing liquid, hydroalcoholic solution, and sodium hypochlorite chloros liquid.

♠ Liquid filling for food, nutrients and medicine product: oral syrup, honey, butter, sauces like salad sauce, mustard sauce, tomato sauce, cilantro sauce, caramel sauce, peanut sauce, etc;

♠ For cosmetics filling: perfume, essential oil of different fragrance; facial cream, lotion, gel, and shampoo, such as shea butter hand cream, protein hair cream, moisture cream, BB cream, CC cream, polypeptide cream, cleanser cream. Cold cream, mattifying cream, hot cocoa cream, eye cream, nutrient day cream, body cream, shaving cream, baby cream.

Monodose plastic ampoule liquid filling sealing machine advantages:

Monodose liquid filling for convenient disposal.

Suits for small-batch filling, small size, portable. easy to carry around, PVC/PE plastic bottle forming, liquid filling and sealing; less package weight. Easy transportation. The advantage of such plastic tube filling and sealing machine is that they are small size, portable; consumers can carry it anywhere without worrying about leakage or break. And because they are small dosage, users can finish quickly, no trouble of keeping them.

Small dosage liquid ampoule Filling and Sealing Process-FFS Machine Operation Video

Small Mono Dosage Oral Liquid Filling Sealing Machines Models We Have.

What’s the difference between JFFS-P5-18 and JFFS-P5-24?

The JFFS-P5-24 model uses one film roll to form a shape, so there is only one side sealing. The package will be nicer.

The JFFS-P5-18 machine needs two film rolls to form a shape, the two sheets of film hot sealed as one piece. There will be sealing rims at the top and bottom of the package.

The JFFS-P5-24 model has the eye mark sensor so as to print symmetric patterns on the package.

The JFFS-P5-18 machine is suitable for plain package or single color package. Less requirement for film design.

The JFFS-P5-24 is easier to use and change spare parts. Better electric control. More expensive touch screen and PLC.

In a word, for multiple filling nozzles machines, we update important parts on the machine to make it easier to use and simpler in fine-tuning. The original regular motor is replaced by a servo motor, which is more accurate and more compatible with the programmed logic controller(PLC). Reduce the 2 rolls of film into 1 roll of film(the old type machine needs 2 pieces of film to run at symmetry and then heat them up into one shape); the current machine only use one roll of film, this film will be folded up in half and form a cavity to fill liquid. This is more stable and the end of filling products should be nicer and can even standing-up. The machine is installed with a photosensor that is suitable for printing patterns that need to be symmetric or the package has strict requirements for printing on the film.

Film Form Fill and Seal Process(liquid dosage form and manufacturing process):

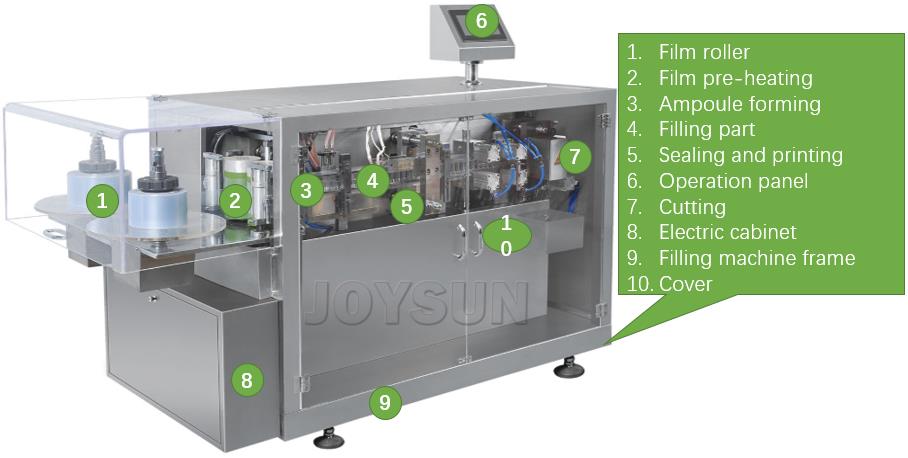

Step1:

Place 2 rolls of film onto film rollers, the film will be pulled tightly forward to the heating station where the electric heater will heat up PVC/PE material to its melting point instantly and form 2 pieces of film into one designed shape via metal mold(the shape is not limited to ampoule, can be any good looking and appealing shapes as long as within our machine size). The maximum depth of the cavity is 12mm.

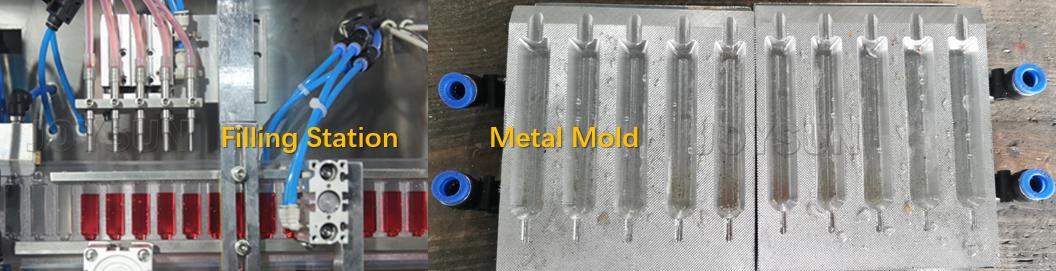

Step2:

The roll of empty ampoules transfers to the liquid filling station where the filling heads inject the pre-set amount of liquid into the ampoules; upon various filling speed requirements, we have a double head filling machine, 5 heads liquid filling machine and bigger ones like 8, 15heads. Our ampoule filling machine dosage: 0-50ml.

Step3:

Then comes top-sealing which we also use heat sealing to the ampoule tips. And we cut them into pieces finally. The liquid filling equipment will trim all unwanted edges of the film to make sure the package neat and tidy.

Step4:

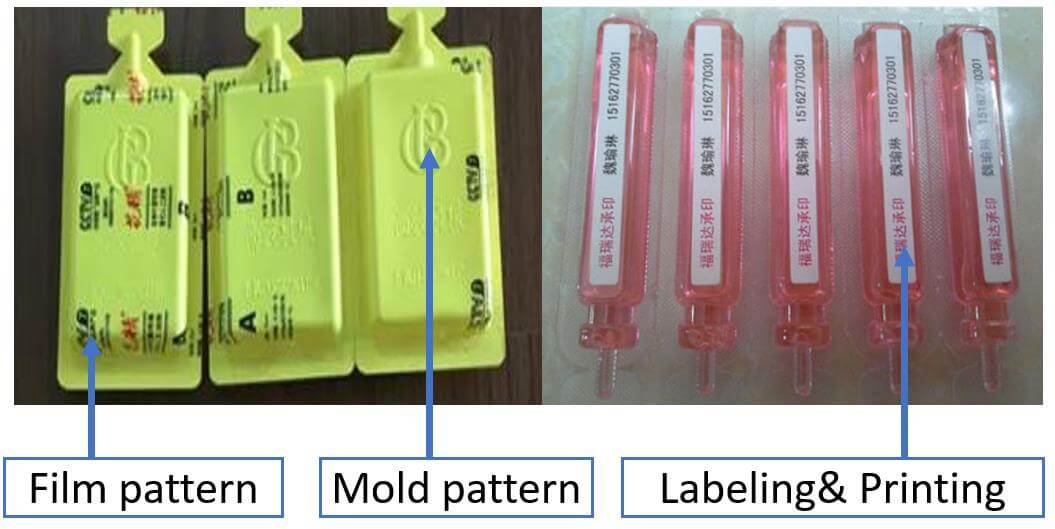

About printing, we’d like to introduce several concepts. The below photos show clearly the difference between each printing and labeling. Buyers can send us the plastic shape with a pattern or not they want, we design a metal mold. Our liquid filling and sealing machine is with batch number and date printing function. If this is not enough, they can add a labeling device to follow our machine. Or when they prepare the film, they can ask film suppliers to print letters and patterns on it. Joysun can also complete a whole line from filling to final packing upon the user’s need.

Other characteristics of JOYSUN oral liquid filling machine

♦ Touch screen operation panel and PLC control program are adopted where all data like heating temperature, filling quantity, sealing temperature, timing can all be pre-set via the touchable screen. The user-friendly design combines all machine functions into one setting table including forming, filling and sealing; batch printing, engraving, and cutting.

♦ The filling part uses precise pharmaceutical degree diaphragm pumps to accurately control filling dosing, filling tube using sanitary degree silica hoses; the whole ampoule filling machine is made of 304 fine stainless steel and the liquid contact part is especially of 316L, conform to cGMP.

♦ Wide production speed range to choose: 2500 tubes per hour to 6000 pieces per hour; small lab use and mass production can all find suitable liquid filling machines from us.

♦ High yield of finished filling products: as high as 95-98%.

Important Tips:

Many buyers mix up the BFS(blow fill and seal) machine with the FFS(form, fill and seal) machine, and even some trading companies can not clearly tell them apart. So let’s take a look at the below picture. The right one plastic ampule is made by blow, fill and seal machine; the left one is from our liquid forming, filling and sealing machine. The Right side ampule should be made in a serious sterile environment and this machine uses plastic grains, not rolling film. The BFS machine blows plastic grains into different shapes directly. And such kind of sterile ampoule filling and sealing machine price can as much as 6 figure U.S. dollars. Products like eye drop, serum, and other high sanitary demand ones come out from the BFS machine. Our plastic tube machine is suitable to make rest products as mentioned in the above passage.

Tags: one nozzle liquid plastic ampoule filler, 5 nozzles plastic bottle filling machine, monodose oral liquid filling machine; single-dose liquid filling sealing machine

1#. What’s the lead time?

Normally the manufacturing day is about 30days, we can dispatch right away if any stock; or sometimes we are loaded with production orders, might be a little more days.

2#. How’s your filling and sealing machine aftersale service?

The engineer is available to go to the user’s site to do installation and training. Making sure operators master the basic usage and working principle of liquid filling machine. The training plan includes installation, filling mold changing, speed adjusting, filling sizing, machine cleaning, and troubleshooting. We provide a 12month warranty.

3#. How is the shipping package and is it possible that buyers install machines by themselves?

The liquid filling and sealing machine is packed in a strong wooden case with strong holding inside to avoid road bump. For small machines, it will be packed as a whole without taking components apart. For big machines, some parts will be taken off for easy packing. We will provide an installation video to show users how to do by themselves.

4#. Can the buyer do the factory Inspection?

All clients are welcomed to visit our factory and showroom. Contact us for the appointment.

5#. How to choose a filling and sealing machine model?

All clients are welcomed to visit our factory and showroom. Any suggestion is welcomed to help us improve machine manufacturing and our service. Contact us for the appointment. We will arrange pickup and transportation when you arrive.

6#. Can you also offer composite film and labeling services?

Yes, we have long term and stable source for PVC/PE composite film, PET/PE Laminated film to use on our liquid filling sealing machine. We also provide labeling machines to finish this packaging line.

Small monodose liquid filling sealing machine demo video+ labeling function.

7# How to choose suitable filling pumps for the liquid plastic bottle filling and sealing machine?

There are 3 types of filling pumps can be used on the liquid filling machine.

1. Piston pump: is for liquid with viscous, not good fluidity as water or oil.

2. Peristaltic pump (standard configuration): is for material with good fluidity, like cream, lotion and etc.

3. Ceramic pump: is for very small dosage filling while requiring high accuracy.

The buyer can send raw material of 100ml to test on our liquid monodose filling machine. The test is free of charge.

8# How to adjust the filling pump for this small dosage liquid filling and sealing machine?

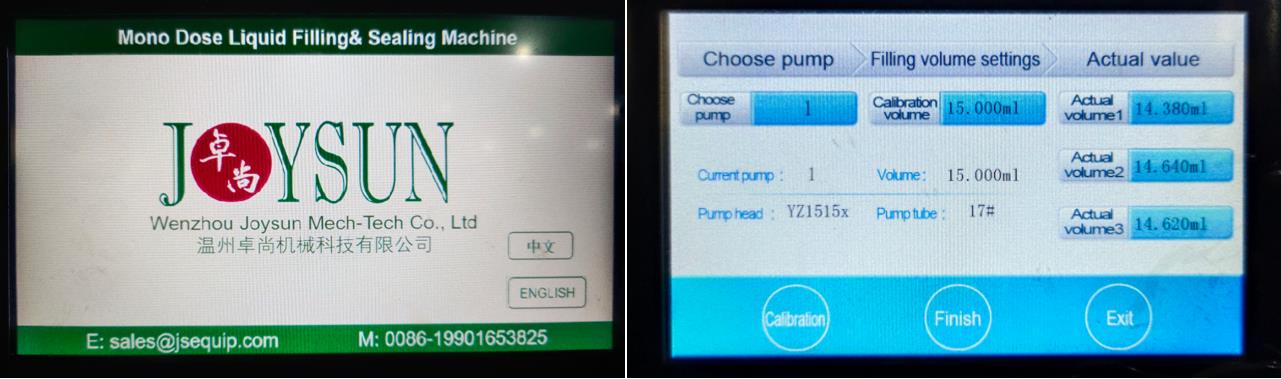

The change and adjustment of pumps are not complicated. Below we introduce the peristaltic pump calibration and adjustment as an example.

Peristaltic Pump Calibration

1.Peristaltic pumps should be calibrated one by one. E.G. Five filling nozzles with five pumps, the calibration should be repeated 5 five times for each.

2.Each time change filling material; peristaltic pump should be calibrated again.

3.Choose the pump to be adjusted, input filling volume on the touch screen. Using a digital weighing scale to get actual weight. Three times. Then input the real data on the touch screen shown as ’Actual volume 1’, ’Actual volume 2’, ’Actual volume 3’; each time after inputting real data, press the ’calibration’ button on the touch screen. After 3 times inputting, press the button ’Finish’. The calibration process is done.

9# How to use the monodose plastic ampoule filling and sealing machine?

We will provide a detailed machine operation video and mold replacement video for our buyers. Besides video and also manual instruction to guide the users. Some brief operation steps as below for reference first.

1)Turn on the device power supply, compressed air, circulating water, and start the device.

2)Turn on/off the machine via the emergency stop at the side of the touch screen,

3)Enter password(******) into the operation interface.

4)Turn on temperature control, to preheat parts of forming and sealing.

5)PVC/PE film placed well and goes through each part of the machine; the preheating temperature reaches the set values to start the machine.

6)When the empty bottle is qualified, run the equipment, check whether the neck and neck preheating sealing units are aligned.

7)The hollow strip passes through the buffer bin and enters the final cutting unit, align cutter through the fine-tuning button, open the cutter through the operating interface.

8)Check whether the filling nozzle is aligned with the bottle mouth, and pump the exhaust, the operation of equipment began filling.

9)Check the filling capacity of each filling pump and adjust to the qualified range.

10)Check whether the bottle seal is firm, the batch number is clear, in accordance with the requirements, open the labeling machine, aligning labels.

11)During the running of the equipment, observe the coordination of the plate and the die, the degree of tightness and the location of the label affixed to the requirements, and adjust them at any time when they are not in conformity with the requirements.

12)The operator shall remove the plate in the preforming unit and the neck unit when the machine needs to stop on the way.

13)When the machine is running, the operator should pay attention to the operation of all parts of the machine at any time. If abnormal happens, it should be stopped urgently.

14)Replacing the film roll, when the film roll is about to be used up, a photoelectric sensor on the film roll unfolding mechanism will trigger the blue light of the color warning lamp. This light tells the operator that new film rolls should be replaced. When the new film is mounted on the mandrel, do not completely lock it, that is, do not tighten the self-locking mandrel knob completely.

Plastic Film Formed bottle

Mobile Perfume or Deodorant, Hyaluronic Acid Sample, Cosmetics and Beauty Drop Sample, Mouthwash Water and etc.