- Home

- Capsule Filling Mach…

Capsule Filling Machine

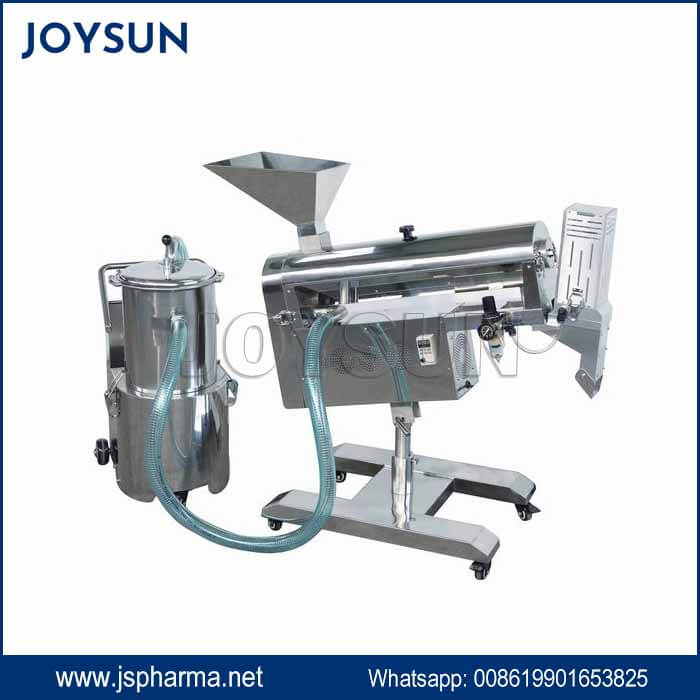

Capsule filling machines significantly enhance productivity by automating the capsule filling process. JS capsule filler machines are capable of handling large quantities of capsules efficiently, streamlining production and reducing manual labor. With the high-speed mechanisms, they have the capability to fill hundreds, even thousands, of capsules per minute, ensuring swift and continuous production.

Capsule filling machines are versatile and accommodate various capsule sizes and types, offering flexibility in production; handle both gelatin and vegetarian empty capsules, making them suitable for a wide range of formulations and customer preferences. The ability to switch between capsule sizes without major adjustments allows for quick changes in production, optimizing efficiency and reducing downtime.

Capsule filling machines have revolutionized the pharmaceutical and nutraceutical industries by offering efficiency, precision, versatility, and enhanced quality control.

The Capsule Filling Machine in Pharmaceutical Manufacturing

Introduction

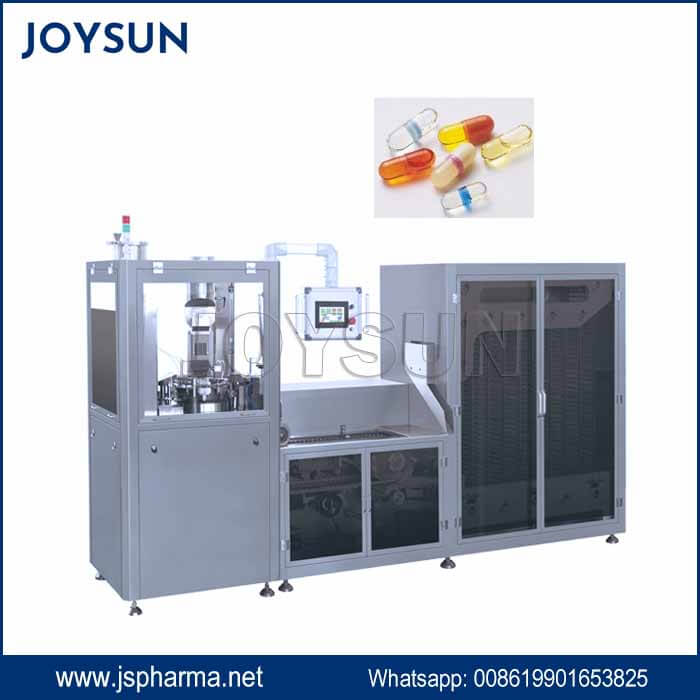

In the world of pharmaceuticals and nutraceuticals, precision and efficiency in product manufacturing are key elements. Among the innovative tools that have transformed the industry is the capsule filling machine. These machines have revolutionized the process of encapsulating medications, dietary supplements, and other powdered or granulated substances, providing accurate dosages and ensuring product integrity. In this article, we will explore the functions, benefits, and recent advancements in capsule filling machines.

The Purpose and Functions of Capsule Filling Machines

Capsule filling machines are designed to automate the encapsulation process, ensuring consistent and precise doses while maintaining high productivity levels. These machines offer several key functions:

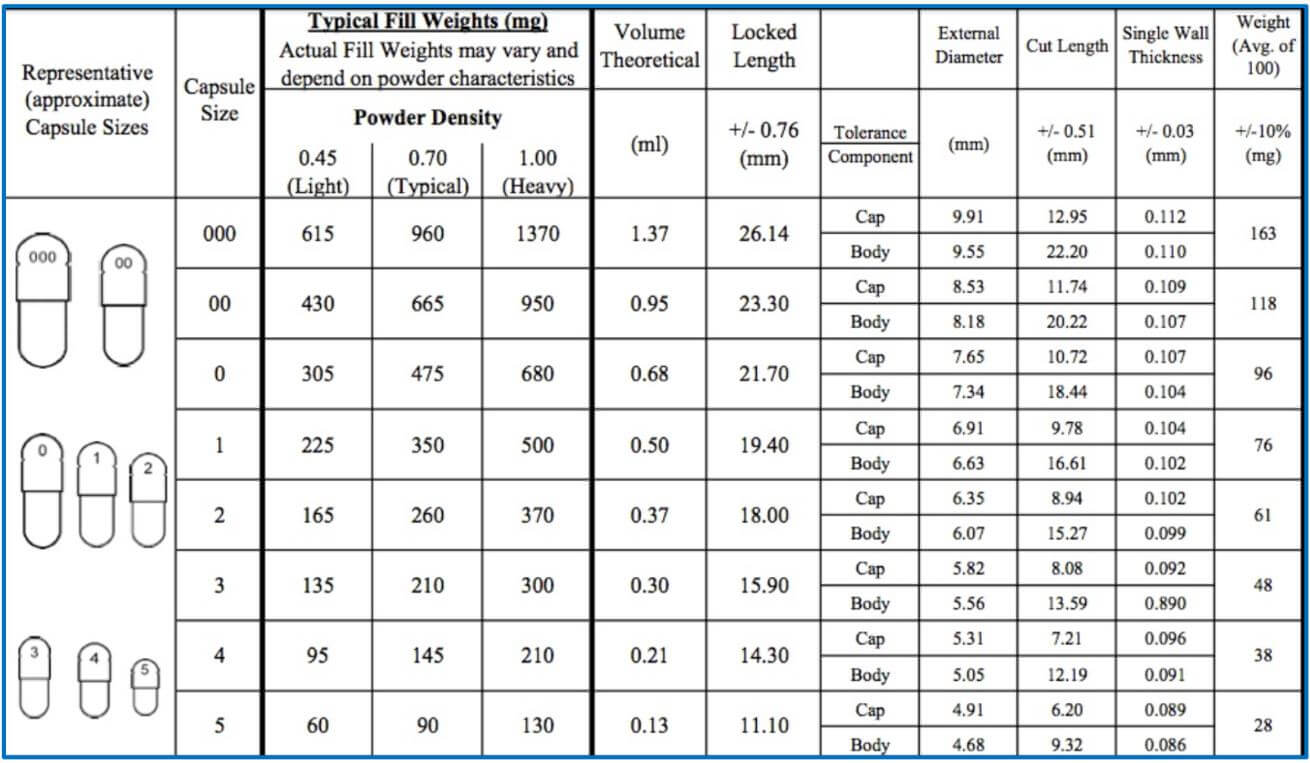

a) Forming Capsules: Capsule filling machines can create two-piece capsules (typically made of gelatin or vegetarian alternatives) in various sizes, ranging from 000 to 5, to accommodate different dosage requirements.

b) Powder Filling: These machines feature mechanisms to accurately dispense powdered or granulated substances into the capsules. They employ advanced technologies to control dosages and minimize variations, ensuring the correct amount of active ingredient in each capsule.

c) Capsule Sealing: Once the capsules are filled, the machines securely seal them to prevent any leakage or contamination. Proper sealing helps maintain the integrity and shelf life of the encapsulated product.

Benefits of Capsule Filling Machines

The utilization of capsule filling machines offers several advantages for pharmaceutical and nutraceutical manufacturers:

a) Increased Productivity: These machines automate the encapsulation process, significantly boosting production capacity. They can fill hundreds or even thousands of capsules per minute, depending on the machine’s speed and configuration.

b) Precise Dosage Control: Capsule filling machines are engineered to deliver consistent and accurate dosages. This ensures that patients receive the intended therapeutic value or desired health benefits from each capsule.

c) Enhanced Quality Control: By standardizing the encapsulation process, these machines reduce human error and ensure uniformity in filling and sealing. This contributes to improved overall product quality and safety.

d) Versatility: Capsule filling machines can handle a wide range of substances, including powders, granules, pellets, and even liquids in some advanced models. This versatility allows manufacturers to encapsulate various formulations efficiently.

Recent Advancements

In recent years, capsule filling machine technology has seen notable advancements, driven by the industry’s demands for increased automation, efficiency, and quality assurance. Some notable developments include:

a) Integrated Systems: Modern capsule filling machines often come equipped with advanced control systems, including HMI (Human Machine Interface) panels and PLC (Programmable Logic Controller) integration. These features enable seamless operation, ease of monitoring, and better control over dosage accuracy.

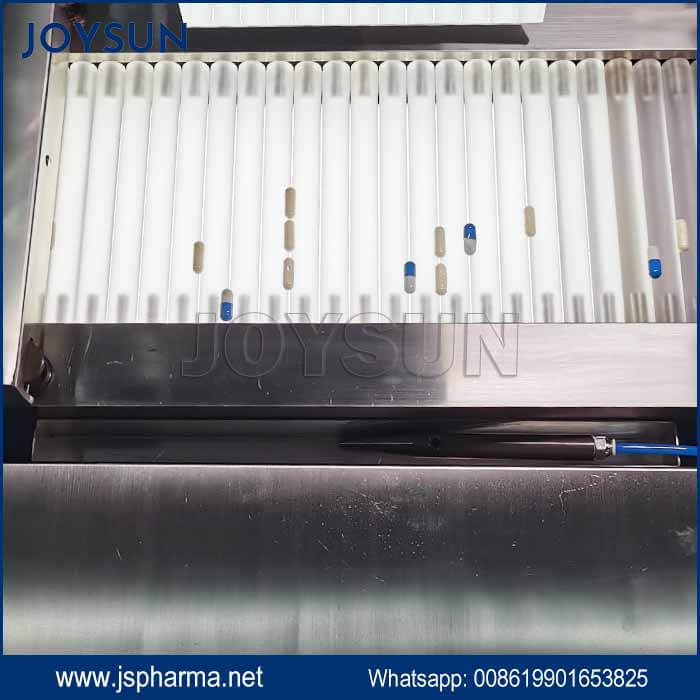

b) Advanced Sensing Technologies: Capsule filling machines are incorporating sophisticated sensors and vision systems. These technologies allow for accurate detection of fill weight, proper capsule placement, and verification of product integrity, further enhancing quality control.

c) Continuous Manufacturing Solutions: Some advancements have been made in continuous manufacturing, where capsule filling machines are integrated into continuous production lines. This approach allows for a seamless and uninterrupted encapsulation process, maximizing efficiency and reducing downtime.

Conclusion

Capsule filling machines have become indispensable tools in pharmaceutical and nutraceutical manufacturing, offering streamlined encapsulation processes, precise dosage control, and improved product quality. With ongoing advancements in automation, robotics, and quality assurance technologies, the capabilities of these machines continue to expand, revolutionizing the industry and contributing to the development of safe and effective medications and supplements for consumers worldwide.

What empty capsule can be used on the machine?

The standard gelatin empty capsule comes mostly in the above sizes and filling quantities.

We can either customize capsule filling mold to the common size range from 000#, 00#, 0# 1#, 2#, 3#, 4#, 5# gel capsules; or buyers send us empty capsule samples, and we make parts according to the real material.

The main shell material is gelatin and veggie material.

Facts to consider before buying a capsule filler

a. How many sets are needed? Our MOQ is one set. More quantity comes with a discount.

b. What’s the size of your capsule?

c. What’s your material to be filled?

d. What’s your factory voltage system? e.g. China is 380v/50hz/3phase/5wires for industrial power system; 220v/50hz/single phase for household usage.

e. Any special requirements?

1. What price for semi-auto capsule filling equipment?

Well, the price differs in several factors: capsule filling speed, operation panel types whether button type or touch screens, and electric components brands. We can make capsule machines upon the buyer’s budget. But for semi-auto capsule filler price ranges from six thousand to nine thousand us dollars.

2. How to use the gel capsule filler machine?

It is very easy, by our installation and operation videos, no need engineer onsite guide, buyers can quickly master the capsule filling process and know how to use, how to adjust, spare parts change, machine cleaning, and maintenance.

3. Can I use this one filling machine to make various gel capsule sizes?

Yes, you can. Only changing the mold is sufficient to do this. As mentioned in the above TABLE, our machine can make different capsules. Buyers can order as many molds as they need.

4. Where to get spare parts for replacement if filling machine parts wear out?

You can contact us directly, we keep a constant stock of regular spare parts and quick-wear ones. We promise to provide spare parts at favored prices as long as you are using our machine.