What Equipment and Machines are for Essential Capsule Manufacturing?

- by JSPHARMA

- November 17, 2023

What Equipment and Machines are for Essential Capsule Manufacturing?

Capsule manufacturing, a common process in pharmaceutical and nutraceutical industries, it relies on various equipment and machines to ensure precise and efficient production. With the ever-increasing demand for encapsulated medications and supplements, the need for advanced, reliable machinery has become more and more important. Here’s a concise overview of the essential equipment that supports capsule manufacturing:

Material Preparation Stage: Powder blender and mixers and granulator will be used in this process to make ready filling material. Small powder blending machine size ranges from 5L to 300L; Bigger is available for customization.

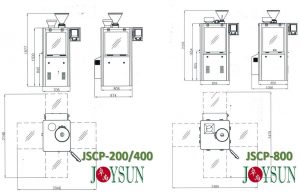

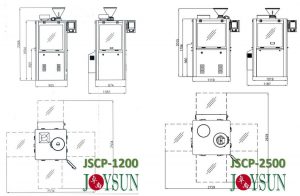

Capsule Filling Machines: These machines are to precisely fill empty capsule shells with the desired dosage of powder and granule, which sell as medication or supplements. They are available in various models, such as manual, semi-automatic, and fully automatic, dosator catering to different production scales.

Capsule Polishers: After the filling process, capsules often require polishing to remove any powder or particles adhering to their surface. Polishing machines ensure that the capsules have a clean, uniform appearance, meeting quality standards for hygiene.

Capsule Sorting Machines: Once the capsules are filled and polished, sorting machines are used to inspect and separate any defective capsules—ensuring that only those meeting quality criteria proceed to the next stages of manufacturing.

Capsule Inspection Machines: Quality control is a fundamental aspect of capsule manufacturing. Inspection machines utilize advanced technologies to meticulously assess the quality, integrity, and uniformity of the capsules. They identify defects, ensuring that only high-quality capsules are distributed.

Capsule Printing Machines: These machines are employed to imprint information such as product identification, dosage strength, and manufacturing details onto the surfaces of the capsules. This crucial step helps in clear and accurate identification of the medication or supplement.

Quality Control Equipment: Instruments like weight variation testers and disintegration testers are essential for ensuring that capsules meet regulatory requirements and adhere to strict quality standards.

The proper selection and integration of these machines directly influence the efficient and compliant capsule manufacturing. Different operations may have varying demands, and the choice of equipment depends on factors such as production volume, product specifications, and industry regulations.

To save users’ time and energy in sourcing, we provide all equipment from A-Z for capsule manufacturing.