Description

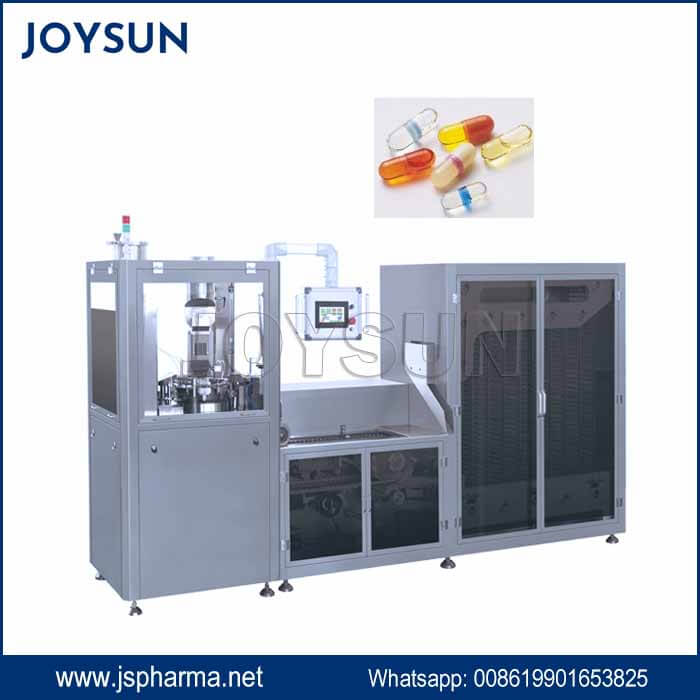

300caps/min Liquid Capsule Filling Machine

Liquid Gel Capsule • Beadlets in Liquid Capsule • Pellets in Liquid Capsule • Capsule in Liquid Capsule

Auto Liquid Capsule Filling Machine Overview

Joysun liquid capsule filling machine newly develops to meet the need to make liquid capsules. It is an innovation based on the conventional capsule filling machine for powder. The capsule filler can only fill powder, while the new liquid capsule filler can hold liquid or paste into the empty capsules. It’s a new formulation for pharmacy usage. Our liquid gel cap-filling machine combines high technology and exclusive performance, it’s function can reach the international leading level. Liquid capsule provides a simple and effective medicine formulation, our technology for this dosage filling is also under constant improvement. The liquid hard capsules can overcome some difficulty filling problems that occur with powder hard capsules. The issues include low bioavailability of insoluble powder, low melting point powder, low-dose material, hygroscopic, and slow-release medicine. The new liquid capsule filler can hold liquid or paste into the empty capsules. It’s a new formulation for pharmacy usage combining high technology and exclusive performance.

With over 15 years of capsule-filling manufacturing technology, independent research, and development, design, we make our liquid capsule filling and sealing machine one of the top qualities. After the capsule is filled, and comes to the sealing process, a strip of gelatin seal will be applied at the mid of the capsule locking. This improves the safety of the product, and makes the liquid cap more stable and stronger in the process of packaging, transportation, and storage. Without liquid capsule sealing, there might be oil leaking.

In the end, our liquid capsule filling& sealing machine meets the high-profile capsule demands of major pharmaceutical companies and healthcare centers.

♣Easy-adjust, easy operation, low maintenance.

♣Built-in counting system.

♣Accuracy and protect the capsule surface.

♣Fast, stable, pharmaceutical degree.

Liquid Capsule Filling Machine Demo Video

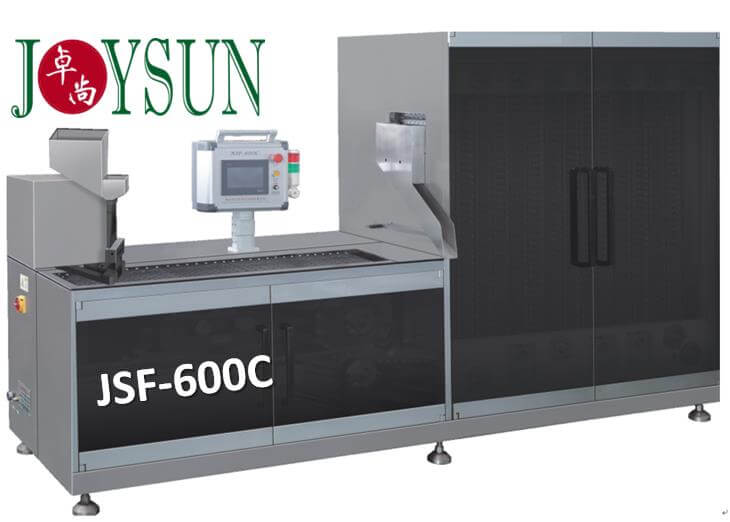

Liquid Gel Capsule Filler Different Models

We have mainly three models of liquid capsule machines with small, middle, and large capacities. Empty capsule size from 0-3# is suitable to use on our machine, other sizes are open for customizing.

With decades of years of capsule-filling manufacturing technology, independent research, and development, we make our liquid capsule filling, locking, and sealing machine one of the top qualities.

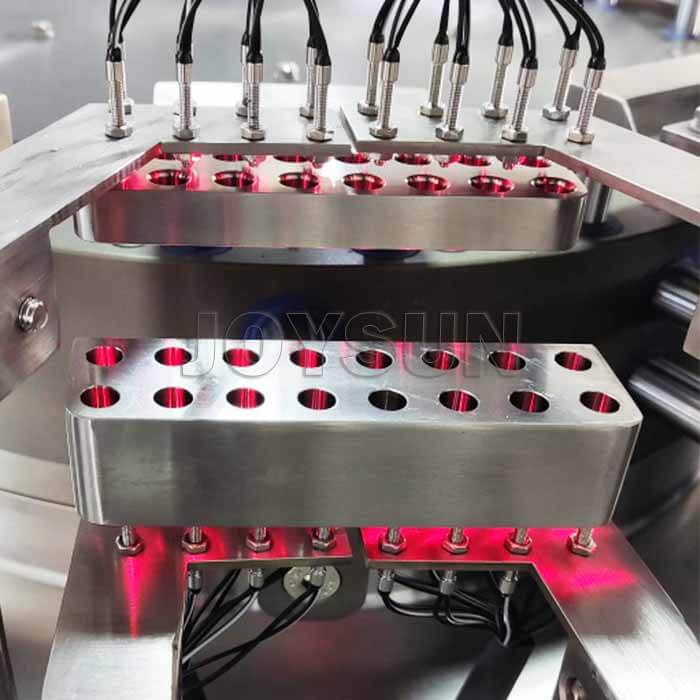

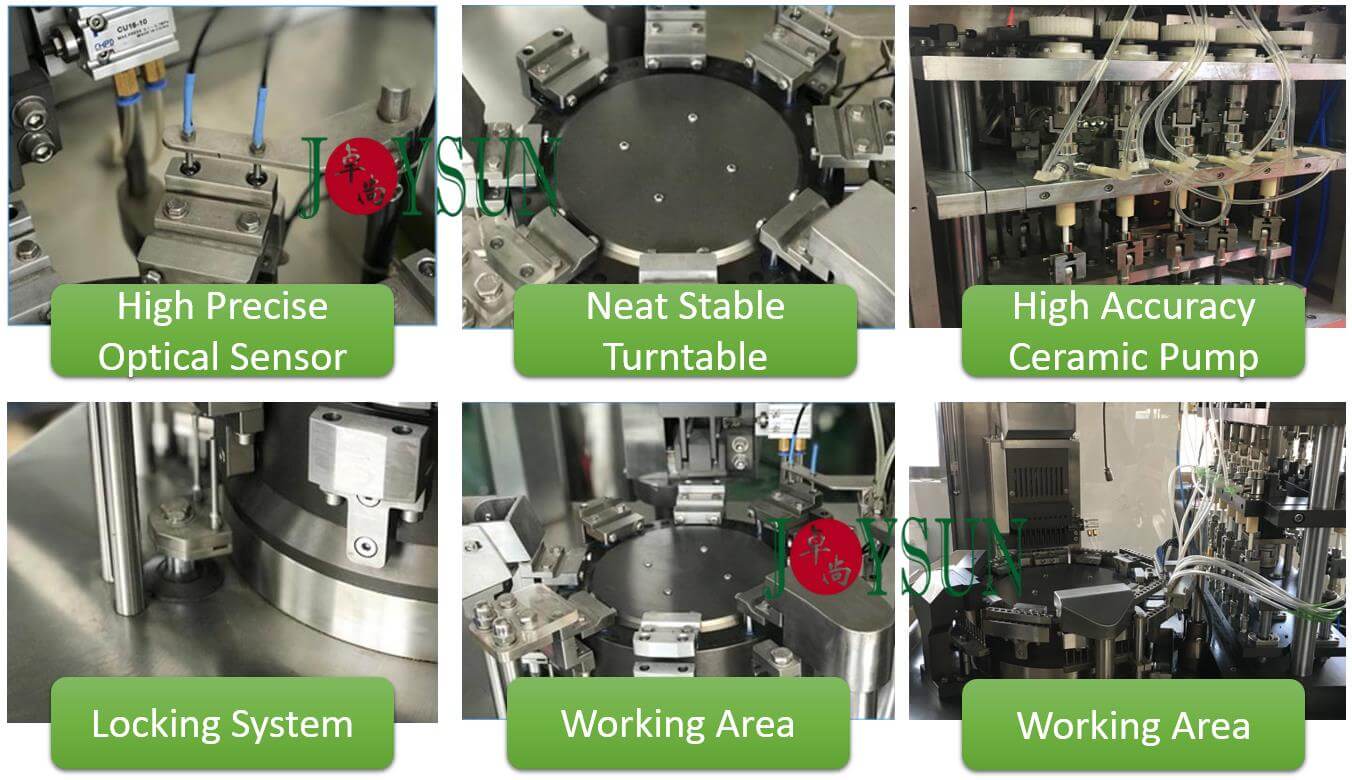

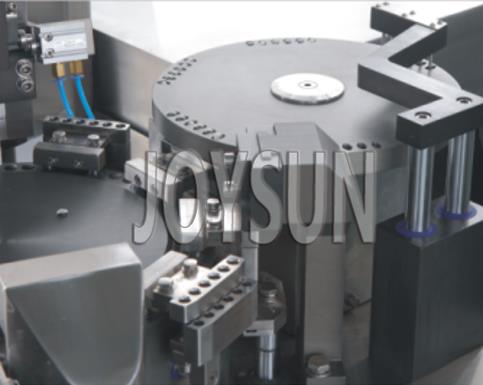

Liquid Capsule Filler Parts Zoom

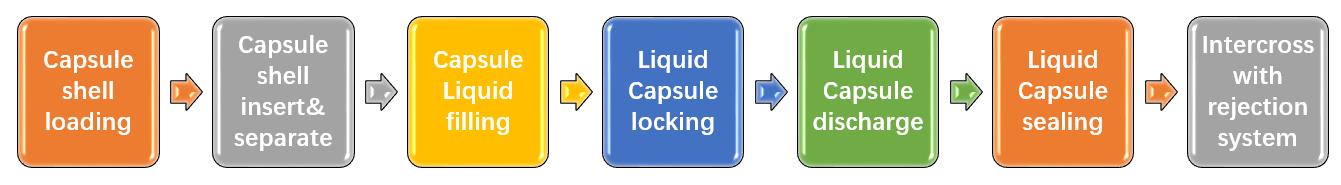

- Empty gelatin capsule loading, the non-split capsule(split capsule with body and cap is not suitable) is suggested to use on liquid capsule filler; loading medicine liquid onto machine hopper too.

- Start the machine by clicking on the touch screen, a series of programmed functions including capsule feeding, capsule body/cap separation, liquid filling, capsule locking, capsule rejection, capsule discharge, and capsule sealing will be finished one by one all in an automatic way. One operator is sufficient. He can oversee the capsule machine’s working status, at the same time interferes with fine-tuning whenever necessary. The machine goes on quite stably.

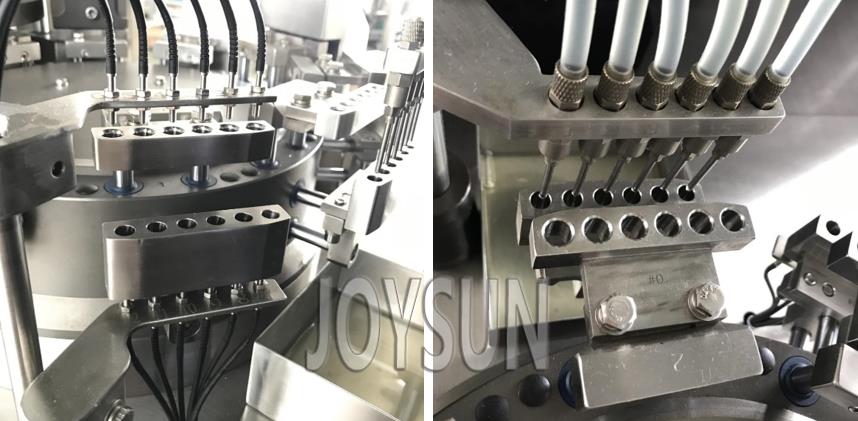

- The high-precision ceramic pump is adopted on the machine to ensure small dosing accuracy, controlling the difference within ± 1.5%. A Servo motor is used instead of a stepping motor. Good quality linear oil-free bearings to reduce action noise, vibration and prolong the machine service time. The machine is covered by a transparent cover to make a fully enclosed filling environment, with no contamination.

- We work with top-brand suppliers for crucial parts or components on our filling machine to ensure a long life of service time.

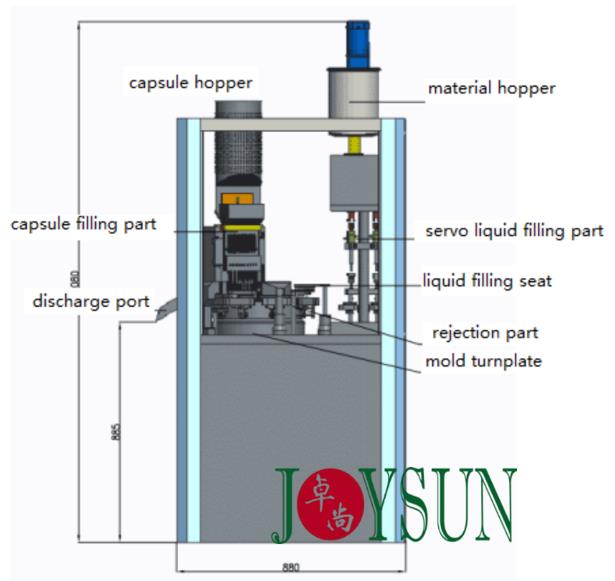

Liquid Capsule Filling Machine Parts View

- For gel cap loading, we must use non-split capsules on automatic liquid capsule filler. (cap body separated capsules are not suitable); loading medicine liquid onto the machine hopper too.

- Start the machine, the following functions such as capsule sowing, separation, liquid filling, capsule locking, cap rejection, capsule discharge, and liquid cap sealing will be finished one by one all in an automatic way. The operator only has to stand by the machine, checking and tuning the machine if something is wrong with the filling machine.

- we use a high-precision liquid filling pump(German liquid ceramic pump)to ensure accuracy, controlling the difference within ± 2%. An imported Yaskawa servo motor is applied for the feeding system. Japanese linear oil-free bearings are used to reduce action noise, vibration and prolong the machine service time. The machine is covered by a transparent cover to make a fully enclosed filling environment, with no contamination.

- The photoelectric sensor is facing each hole to make sure there is a capsule inside and there is filled material inside; when nothing is detected, the rejection system works.

- For major and crucial parts of the machine, we cooperate with top-brand suppliers

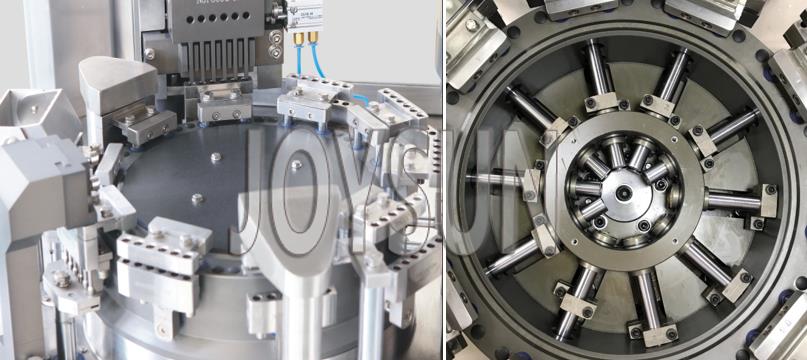

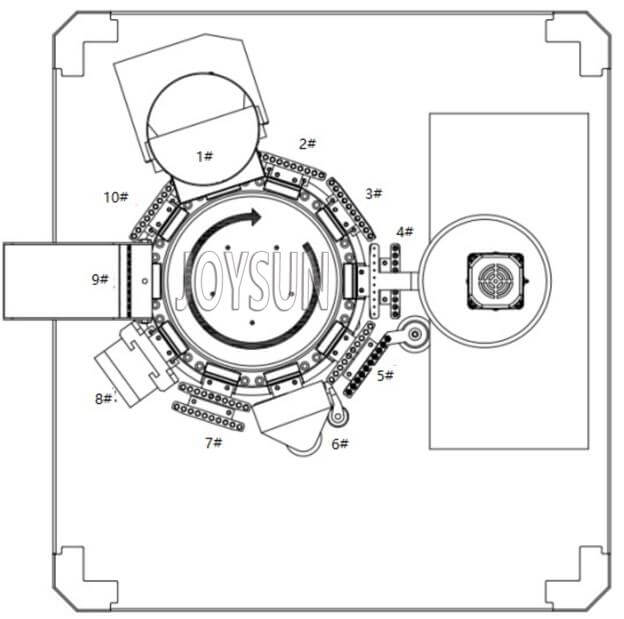

Liquid Capsule Filling Station

The 10-station rotary disc adopts integrated processing to achieve a compact structure, no splicing gap, good sealing, easy to disassemble, and easy to maintain. The upper and lower modules move separately (the lower mold is horizontally stretched and the upper mold is moved vertically). The fixed bracket shaft seal of the upper and lower modules adopts the oil-proof and dust-proof lip seal. It can be repaired and maintenance-free within three years without any dry sound.

The approximate working principle of each station:

1# station: capsule separation.

2# station: the upper and lower capsule mold separation.

3# station: The photoelectric detection capsule is separated or normal.

4# station: filling liquid.

5# station: add smaller capsules (for capsule in capsule/pellets in capsule).

6# station: capsule detection and rejection.

7# station: vacancy.

8# station: lock capsule.

9# station: finished capsule discharge (connected capsule sealing machine).

10# station: the upper and lower molds reset.

High-Precision Ceramic Pump

The liquid filling system adopts a high-precision ceramic pump and a servo motor dosing system to control the difference in liquid material loading in the capsule to about ±2%. The advantages of such a filling pump and why we choose this among all other kinds of filling devices as it is a crucial part of the oil gel capsule filling machine.

Properties of Ceramic Filling Pump

♣Low maintenance cost

♣High tech ceramics

♣Fast assembly

♣Hardness is higher than stainless steel pump coatings.

Silica Filling Hose-Pharmaceutical Degree

The fast reaction speed, fiber-optic sensing can realize non-contact detection with high precision, high resolution, and good reliability. The device can quickly detect whether the hollow capsules are normally separated during the production process, such as non-normal unseparated hollow capsules, or optical fibers. After the system detects the collected data at the filling station and the kicking station, the equipment runs to the filling station. According to the data analysis of the fiber inspection system, the filling station stops adding liquid, and the equipment runs to the kicking station. The abnormal unseparated hollow capsules are removed to ensure the stability of the equipment during the production process.

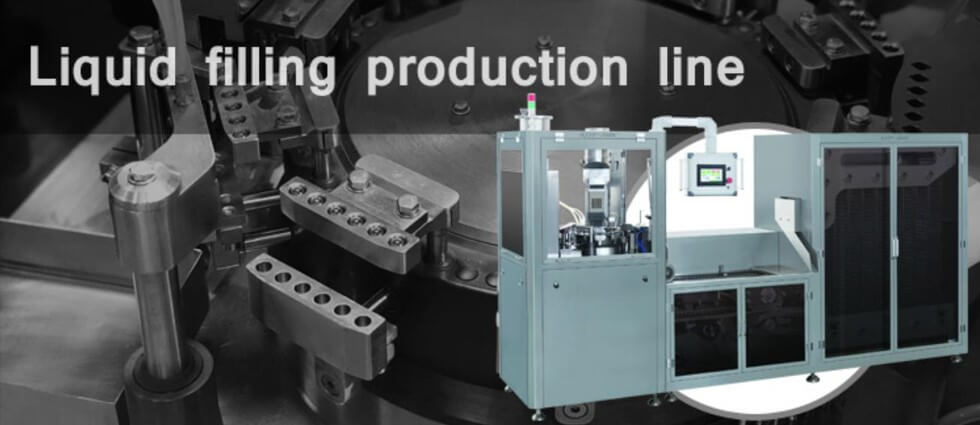

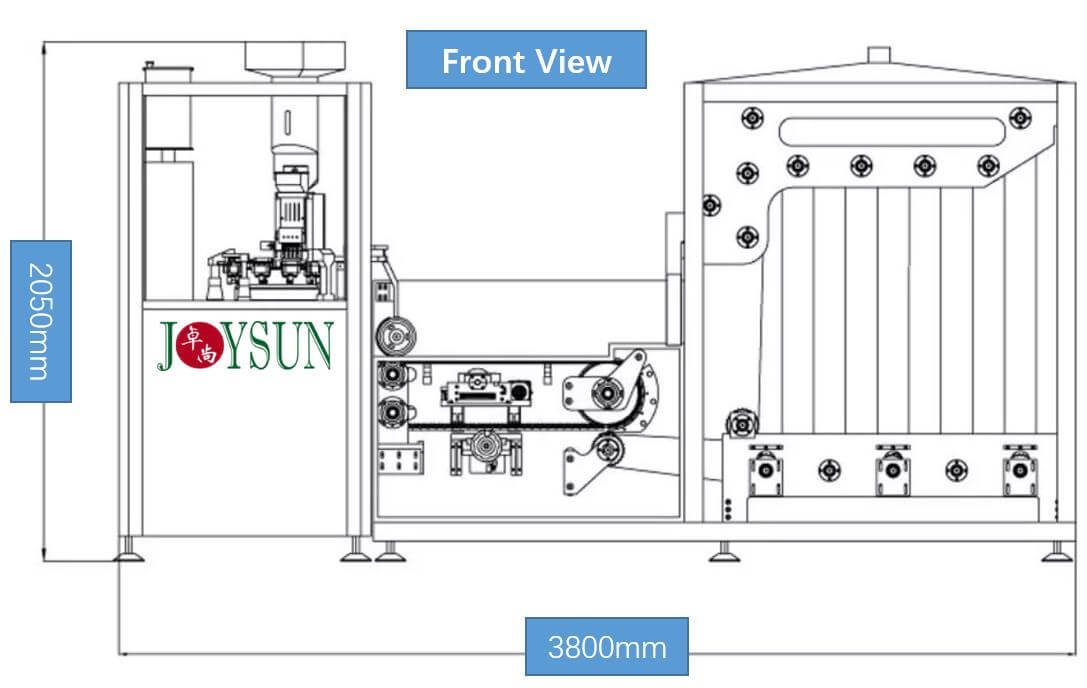

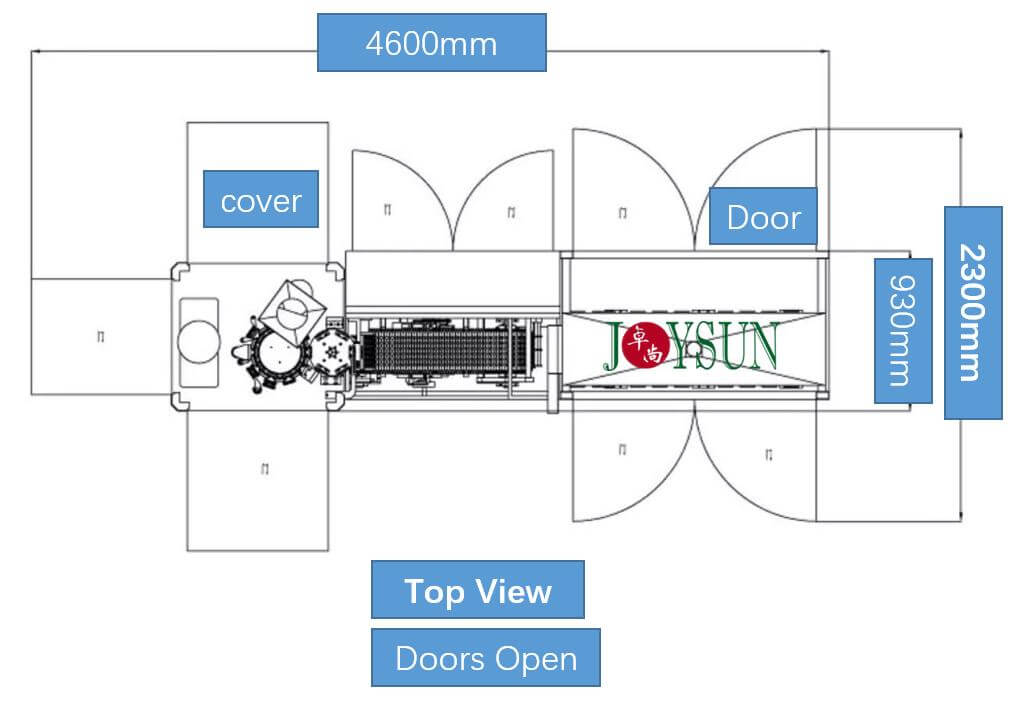

Liquid Capsule Machine Layout and View

Let’s take a look at the size and layout of liquid cap filler from top and front. When you buy it, must make sure enough cleanroom space is spared for it. And you also need to consider the operation and maintenance space for the machine during use, debugging, and cleaning.

Frequently Asked Questions About Oil Capsule Filling Machine

Q1. What Liquid Material can be filled into a capsule?

We can fill many types of medicine liquid into the liquid capsule, the types we already tried is honey, edible oil for food, herbal oil for medicine, and oil/powder paste or mixture. For first time buyers or users, you can send us material samples to test on the machine.

Q2. What is the material of the empty capsule used for this machine?

The material of the liquid-filled empty capsule is the same as regular ones: two-pieces gelatin capsule or HPMC (hydroxypropylmethylcellulose) with cap and body. The capsule size also can refer to the regular empty capsule.

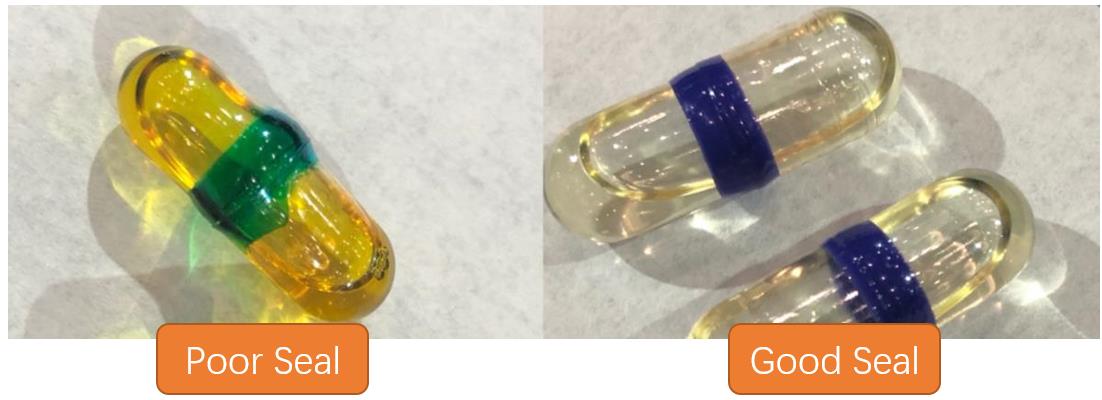

Q3. Can I only buy a capsule filling machine, not buy the sealing machine? And why I also need to buy the capsule sealing machine?

Well, this question is based on your filling material. For example, if your material is just like edible oil, I am afraid the answer is YES. You need to purchase the liquid capsule filling and sealing machine as a whole. Because without sealing, the liquid will leak from the capsule. If your material is with poor fluidity and not easy to leak, you can try with only capsule filler first. This needs time to prove. Our liquid capsule sealing machine has been improved to make a nice and neat sealing strip.

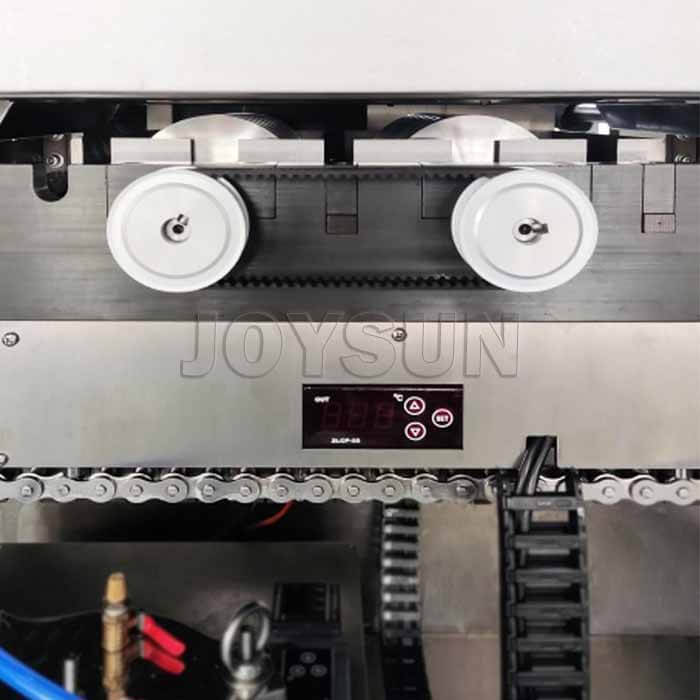

Sealing Machine for Liquid Filled Hard Capsule

Does liquid leak from the capsule? It is a hot question about liquid hard capsules. Due to the lack of qualified empty capsule that can absolutely lock liquid medicine inside the capsule, there is always the risk of leaking whether major or minor. To solve this problem, we strongly recommend the liquid capsule sealing machine whose function is to apply a sealing ribbon in the middle of the hard capsule.

A capsule sealing machine changes the looking of a capsule in an apparent way. The good liquid capsule sealing machine must be very stable and reliable to apply an even layer of gelatin surrounding the locking part of capsules. The layer of the gelatin ribbon should not be too much or too less. Too much slow down the drying process and make the capsule not appealing; too less will affect the sealing result. Our newly improved JSF-600LB liquid capsule sealing machine can links directly to liquid capsule filler. It has a horizontal driving way to seal the liquid capsule, but a vertical driving system during drying. The vertical conveying of the liquid capsule during drying can speed up the drying process due to the installation direction and drying fan.

Q4. What’s the material of the sealing strip?

There are two materials that can be used for the sealing strip on the locking place of the capsules. One is food degree gelatin made of pigskin. Another one is vegetable material. If you are making liquid capsules for vegetarians, you can use HPMC empty capsule together vegetable sealing strip. One kilogram of this sealing material can apply to hundreds of thousands of capsules. No big raw material cost. Only the sealing process might take hours to finish because we need time to let the sealing strip cool down.

Q5. What is the machine delivery time?

Machine lead time is 35-40days upon receipt of downpayment and technical confirmation. In the case of urgent need, contact us to discuss the possibility of early manufacturing or adjusting dispatch.

Q6. How about the after-service and warranty?

We make the guarantee time 12 months from the machine’s arrival in the buyer’s facility and we have a professional team with an experienced technician to serve abroad and do the best after service to assure the machine whole life usage.

Q7. Do you supply all the spare parts related to the machine?

Yes sure. Major and crucial parts on the machine, we cooperate with top-brand suppliers. And we supply all the spare parts which are related to the machine. Feel free to contact us anytime.

Q8. How about the payment term?

Thank you for your support and glad to cooperate with your esteemed company. The payment method can be a 30% deposit in advance and 70% before shipment.

Q9. How to deliver the liquid capsule filling machine?

The machine can be sent by both ship and air.

Ultra Fast Capsule Filling Machine: https://www.jspharma.net/ultra-fast-capsule-filling-machine-fully-automatic/

Automatic Capsule Filling Machine: https://www.jspharma.net/automatic-capsule-filling-machine-for-sales/