Description

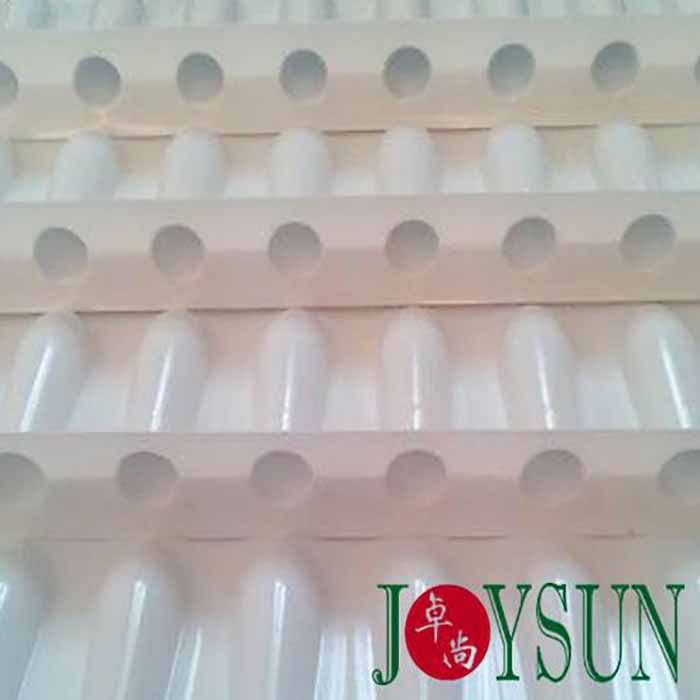

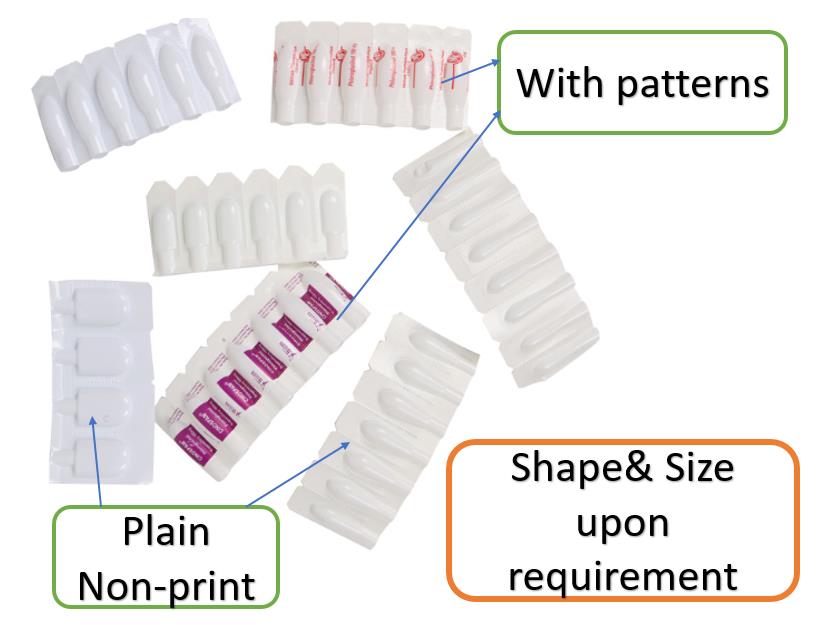

Qualified Preformed Suppository Shell

Preformed Suppository Shell On sales

Preformed Suppository Shell On sales

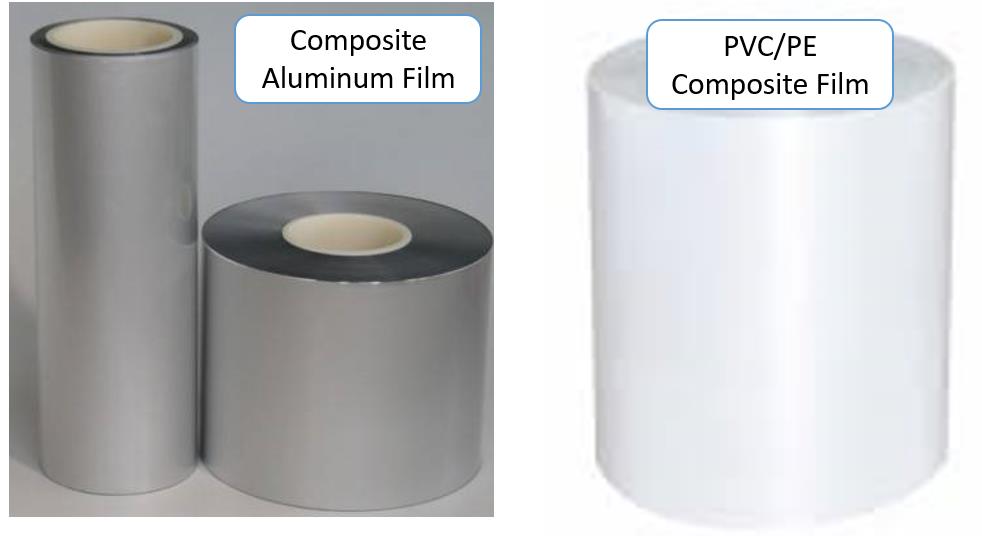

Email us for a quick quotation on laminated PVC/PE film or preformed suppository shell

Characteristics

♠ Anti-oxidation, light-shading, moisture resistance, and good sealing.

♠ Easy to carry after made into pharmaceutical dosage, easy to peel off.

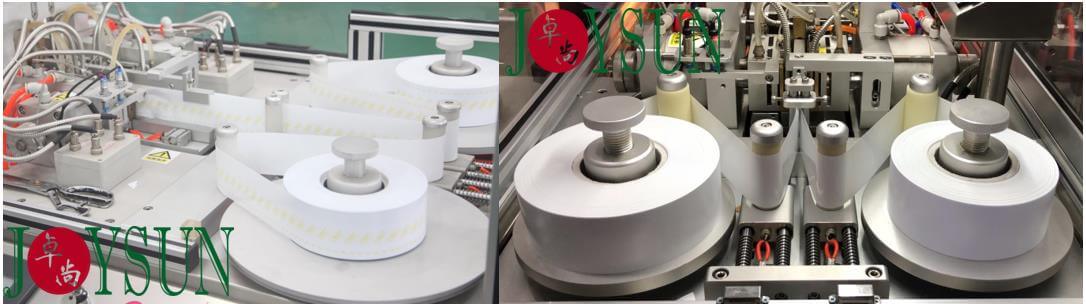

♠ Excellent properties: a wide range of tolerance for temperature change whether low or high temperature; corrosion resistance; suitable for high-speed automated packaging under various operation conditions.

♠ Adopt non-peelable heat-seal coating, which can be heat-sealed with PVC, PVDC / PVC, PP, and other plastic substrates.

♠ Single-sided and double-sided printing can be done according to the buyer’s requirement.

Samples, Packing and Shipment