Description

Tablet Strip Packing Machine

Introduction:

Strip Packing Machine is a device to make products into the strip packs. The Strip pack machine is widely used for pills, tablets in pharmacy; for food like candies, effervescent tablets, Altapharma; and also for other unit dosage packing such as throat lozenga, honey lozenga; another consumer products like mosquito-repellent incense mat and electric mosquito mat. The strip pack is good for the packing requirement of moisture-proof, light-proof by using Alu/Alu; or plastic/plastic film material. Here we mainly introduce tablet strip packaging machines in the pharmacy industry. It is an alternative packaging form for blister packing.

Strip Packaging Machine is widely used in hospital dosage room, laboratory institute, health care product, middle-small pharmacy factory. Our strip filling and sealing machine is of compact design only needing a small room space; easy operation by only pressing buttons is enough; PVC board length convenient adjusting; stable working performance and long service life. This machine adopts human-machine interface operation, PLC programming, frequency conversion, and speed regulation, the high degree of automation, easy operation combines the complete functions into modules.

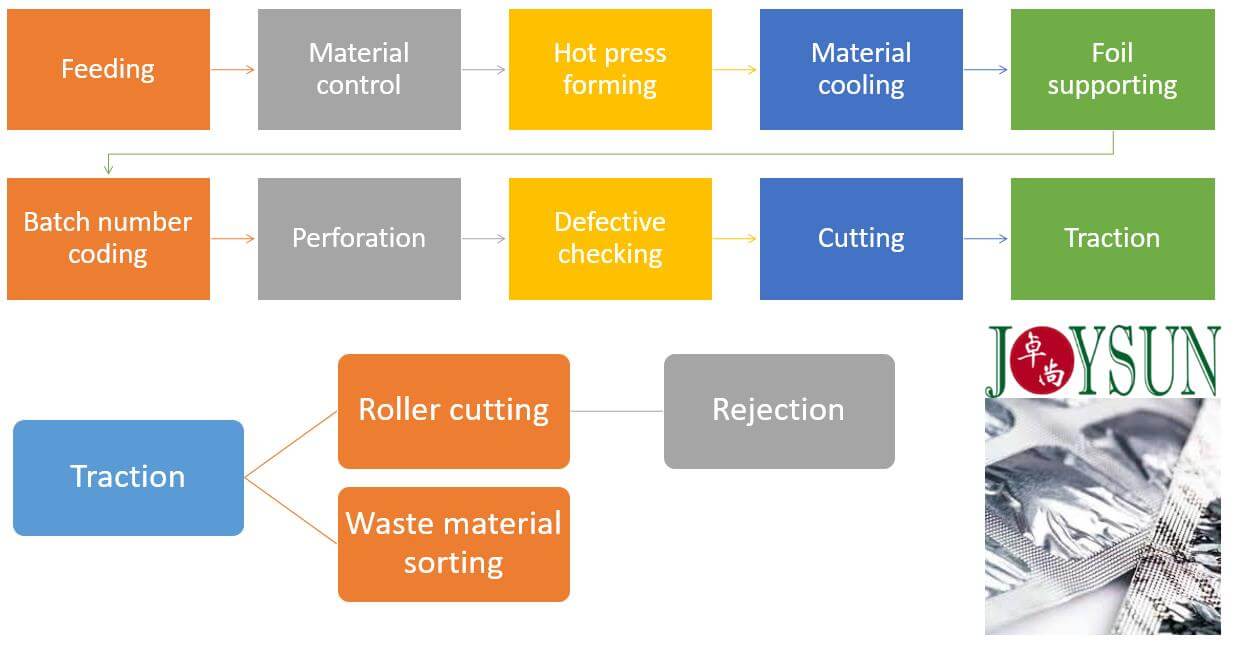

Let’s take a look at how strip packing machine works? The process to make strip packing:

What can be used as strip packaging material in the pharmacy:

1. Regenerated cellulose 2. Soft Aluminum 3. Paper / Polyethylene / Foil

Pharmaceutical Strip packaging samples:

Tablet, Pill, Altapharma, Honey Lozenga Strip Packaging Machine Review:

Tablet Strip Packing Machine Performance and Characteristics:

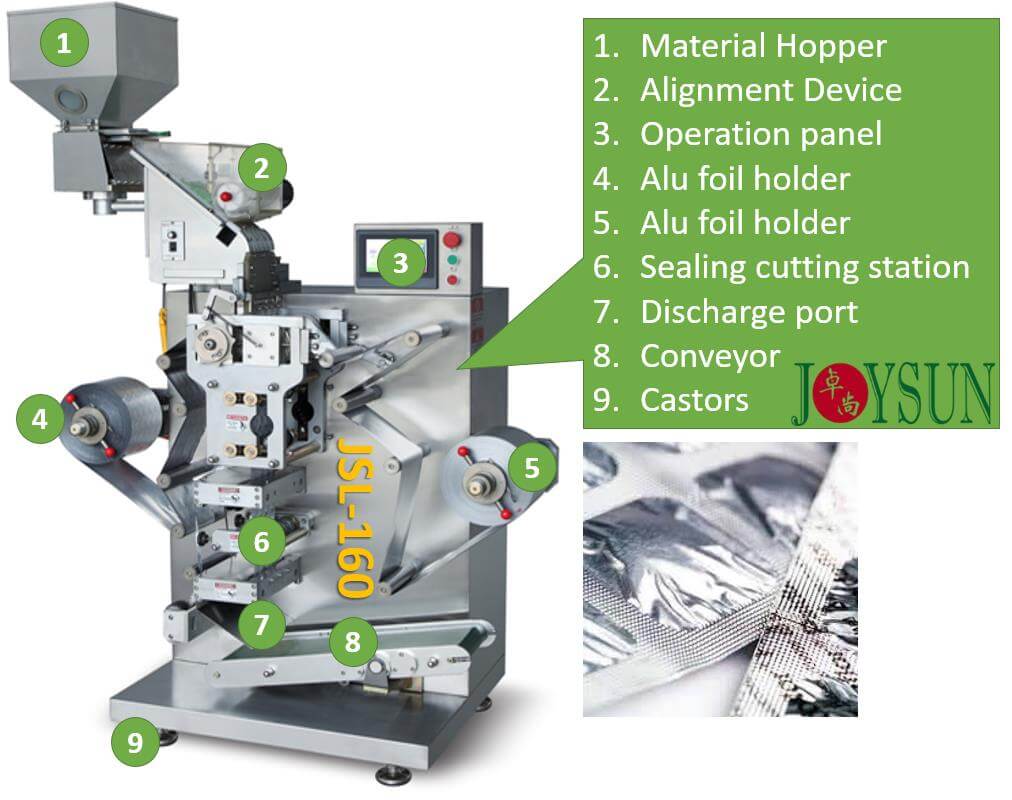

1. The hopper feeding adopts vibration system and photosensors so that during tablet falling into each lane, powder or debris will be effectively removed from pills;

2. Using PLC(Programmable Logic Controller) to combine functions such as tablet counting, vertical and horizontal direction embossing, slice cutting, edges trimming, and batch number printing into modules. Users can easily change or set the value via the touch screen. Most operations are automatically done, only need a little man interferes if something goes wrong or needs minor adjustment during machine operation.

3. The diameter of the hot-pressing wheel can be adjusted within the range of 110-140mm which gives a wider choice for strip packing width.

4. The cutting process adopts an electronic detector and PLC, the user can easily increase or decrease the pill number at the length side of strip packing, and this adjustment doesn’t require mold changing; Only need to set value in touch screen. An extra set strip pack pulling device is installed to help a more smooth conveying of strip pack.

5. Our specially designed and the manufactured cutter is of more clean and accurate cutting, suitable for various materials, longer blade life, no need to change the blade when changing the mold;

6. The optional optical fiber detection device can effectively reject dis-qualified packing, the success rate can be 99%.

Pill Strip Packing Machine Work Process:

Tablet strip packing machine, how many models we have?

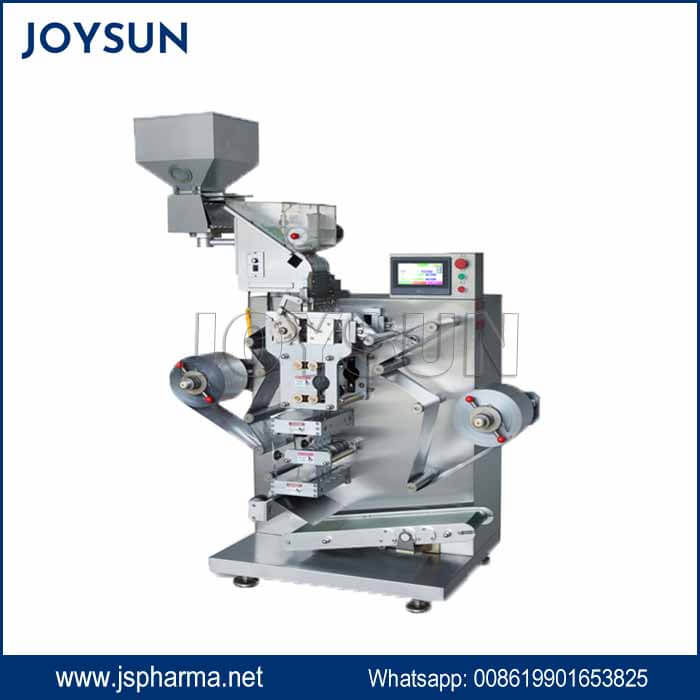

For small to medium size of soft Alu/Alu double strip machines, we have three models JSL-160, JSL-260, JSL-350. The machine can also fill and seal irregular shapes of pellets as unit dosage packaging and four sides sealed packing.

Pill, Tablet Candy Strip Packing Machine ZOOM

Major Difference between strip packaging and blister packing:

Many buyers mix up the blister packing machine with strip packing machine, and even some trading agency can not clearly tell them apart. So let’s take a look at the below picture. The upper one is made by blister packing and sealing machine; the lower one is from the strip packaging machine. Or we can also say, capsule blister machine can work with hard aluminum packing and aluminum plastic packing; while the strip pack machine can do with soft Alu foil only.

1#. What’s the lead time for the strip packing machine?

The manufacturing cycle for one set machine is about 30days, but we can dispatch right away if we have any stock, or sometimes we are loaded with production orders, might be a little more days.

2#. How’s your strip package machine service?

We have clear photos, videos, and manuals to show to buyers about the installation and operation of the machine. If anything is confusing during operation, the buyer can contact us anytime, we will respond quickly to help to solve the problem. We also provide a 12month warranty. The engineer is also available to go aboard for onsite training.

3#. How is the shipping package and is it possible that buyers install machines by themselves?

The pill packing machine is packed in a strong wooden case with strong holding inside to avoid road bumps. For small machines, it will be packed as a whole without taking components apart. For big machines, some parts will be taken off for easy packing. We will provide installation video to show users how to do by themselves.

4#. Can the buyer do factory Inspection?

All clients are welcomed to visit our factory and showroom. Contact us for the appointment. We will arrange to pick up and transportation within your visit.

5#. How to choose a strip machine model?

Email us your requirement and your strip packing need, we will design mold and send you suitable proposals. You are in good hands.