Description

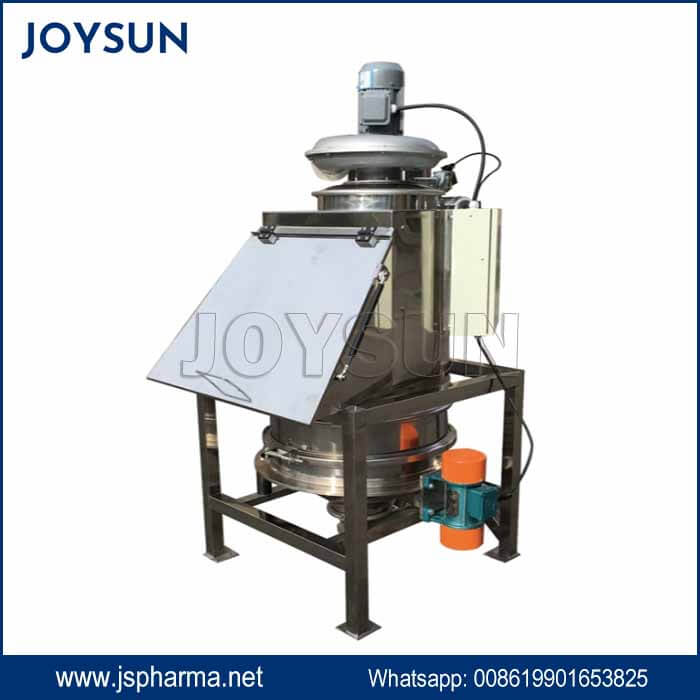

Dust-Free Bag Dumping Station| An Efficient and Clean Powder Loading Solution

Bag Dumping Station Introduction

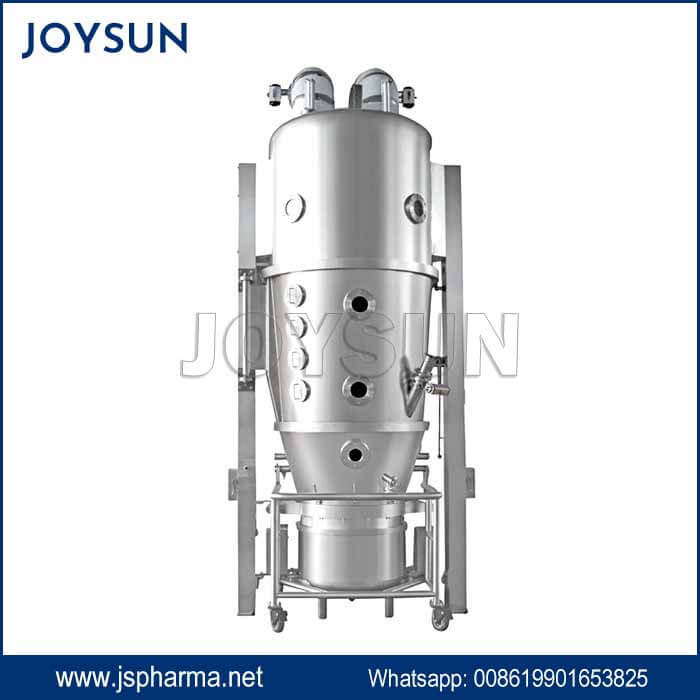

The Dust-Free Feeding Bag Dumping Station is a material transfer device that utilizes negative pressure dust collection technology, specifically designed for bag opening and feeding during production processes. It not only stores materials but also conveys them to downstream processes while working in conjunction with a dust collection system to effectively prevent dust from flying, ensuring a clean and safe production environment. It is widely used in powder blending. In the mass production line, bulky bag unloader is also used.

Sack Dumping Station Features

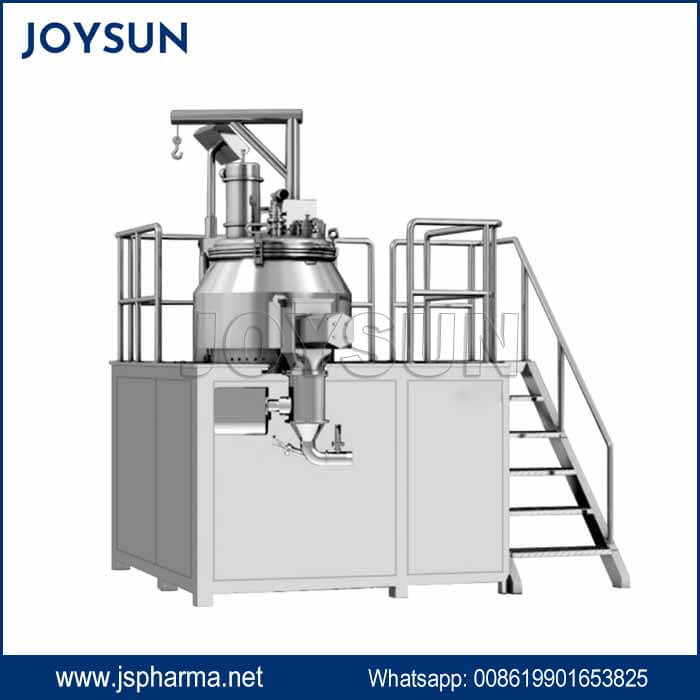

- Compliant with Regulations: Strictly designed and manufactured in accordance with FDA, GMP, and cGMP regulations, meeting high-standard production requirements.

- Easy to Clean: Filters are easy to remove and clean, facilitating production with multiple material varieties.

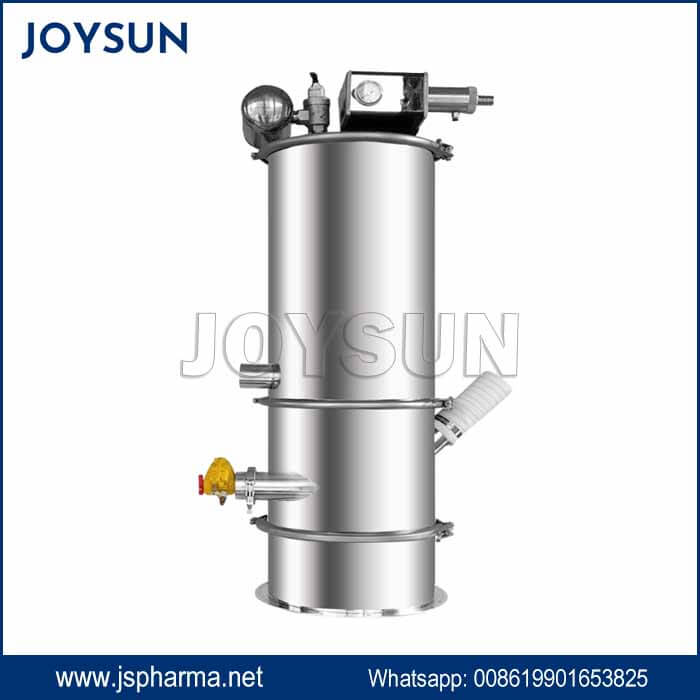

- Efficient Filtration: Employs gas-solid separation filtration technology to effectively prevent dust from flying and minimize material waste.

- Intelligent Backwashing: The filter backwashing cleaning device can intelligently clean the filter at regular intervals to ensure filtration efficiency.

- Sealed and Clean: Overall sealed design eliminates leakage and cross-contamination, allowing direct installation in clean rooms.

- Humanized Design: The feeding platform is ergonomically designed for comfortable standing operation.

- Flexible Adjustment: The vibration motor’s excitation force is adjustable to meet the needs of different materials.

- Material Screening: Materials can be directly screened during feeding to break up lumps and intercept foreign objects, ensuring material quality.

- Convenient Disassembly: The screen can be easily and quickly disassembled without tools.

Small Bag Dumping Station Working Principle

The small bag dumping station utilizes a dust removal filtration operation platform to prevent dust from escaping during manual feeding. After unpacking, the material enters the conical chamber inside the feeding station. The dust generated during this process is adsorbed under negative pressure airflow and then intercepted by the filter cartridge. The clean air then passes through the filter cartridge and is discharged by the blower.

To maintain the operating resistance of the blower within the allowable range, the filter is regularly backwashed for cleaning. The backwashing process can be carried out in two ways: automatic backwashing and manual backwashing. Automatic backwashing is controlled by the system, while manual backwashing requires manual operation.

Small Bag discharger Applications

The Dust-Free bag dumping station is also known as bag discharger widely used in the following industries:

- Pharmaceutical: Traditional Chinese medicine powder, Western medicine powder, pharmaceutical raw material powder, etc.

- Metal and Metallurgy: Lead powder, zinc oxide, titanium oxide, casting sand, diamond powder, aluminum powder, iron powder, various metal powders, etc.

- Chemical: Resin, paint, pigment, rubber, carbon black, activated carbon;

- Ceramics: Glass, ceramics, ceramic slurry, grinding materials, refractory bricks, raw limestone, mica, aluminum oxide, calcium carbonate (heavy), etc.

- Food: Sugar, salt, MSG, starch, milk powder, soy milk, juice, rice flour, dehydrated vegetables, juice, yeast solution, pineapple juice, fishmeal, food additives, etc.

With its efficient dust control capabilities and user-friendly operation, the bag dumping station provides a safe and reliable material handling solution for various production environments.