Description

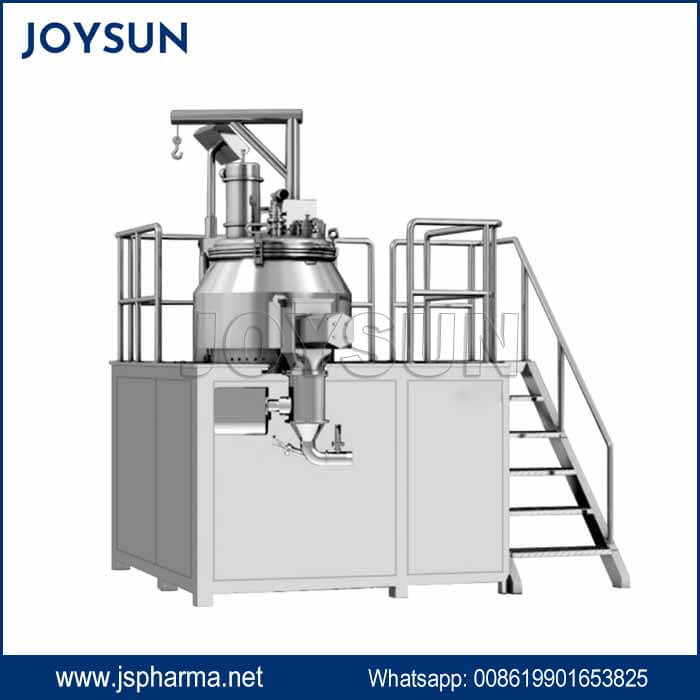

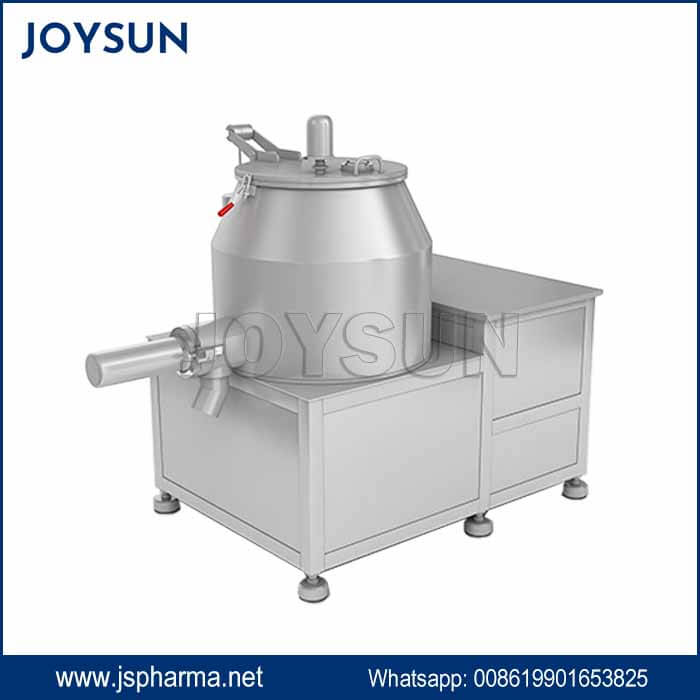

Wet Granulator

Wet Granulator for Powder Preparation

What is Wet Granulation?

A wet granulator is a machine that transforms powdered materials into granules. It is widely used in various industries, including pharmaceuticals, food, and chemicals. A wet granulator working process can be summarized into four main stages: feeding, mixing, granulation, and discharging.

What’s the Working Principle for Wet Granulator

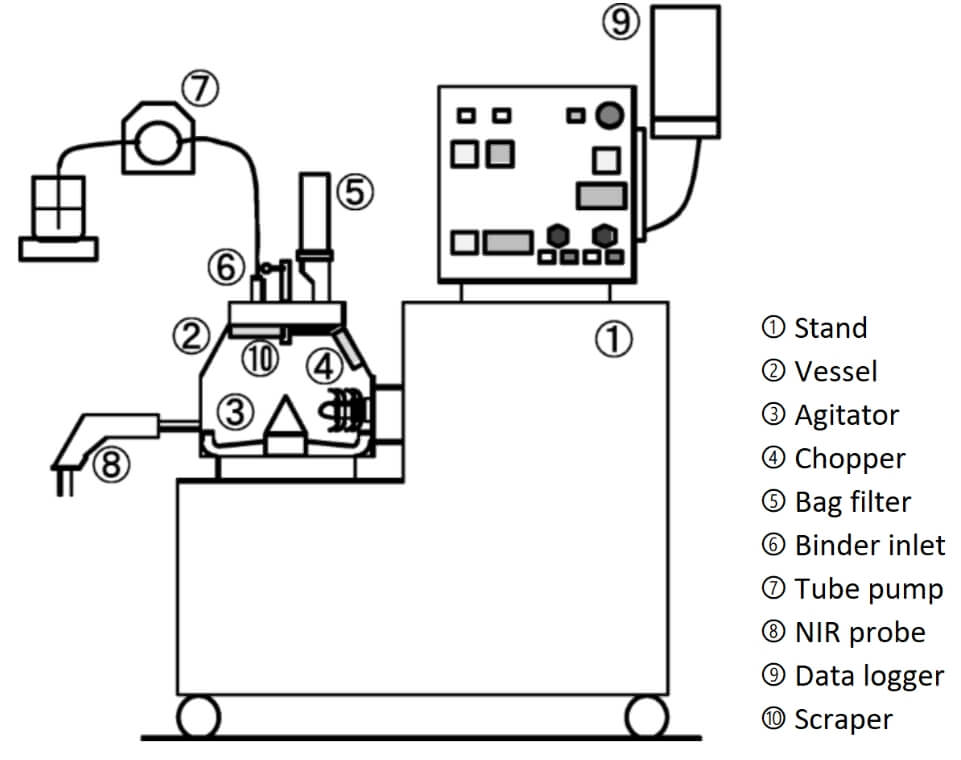

Feeding Stage

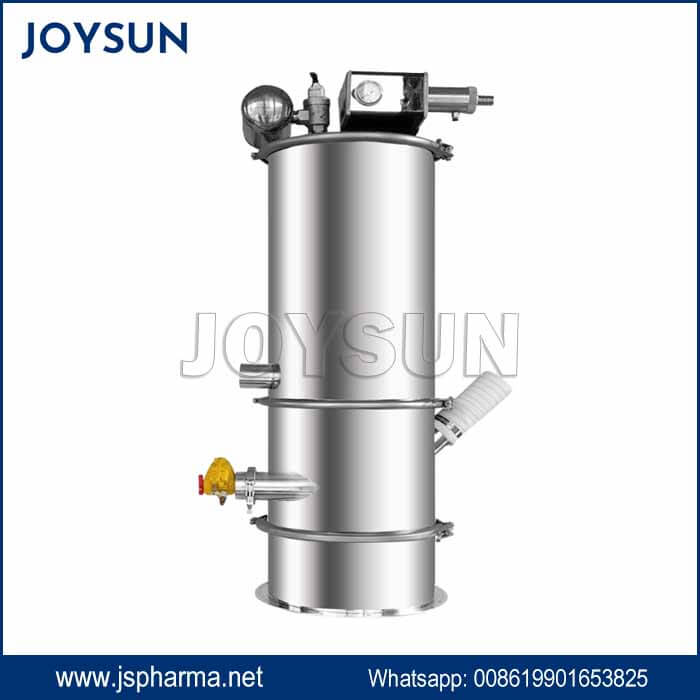

Wet granulators can employ either vacuum feeding or other feeding methods. Vacuum feeding can be further classified into intermittent and continuous types. Once the feeding process is complete, the equipment starts operating.

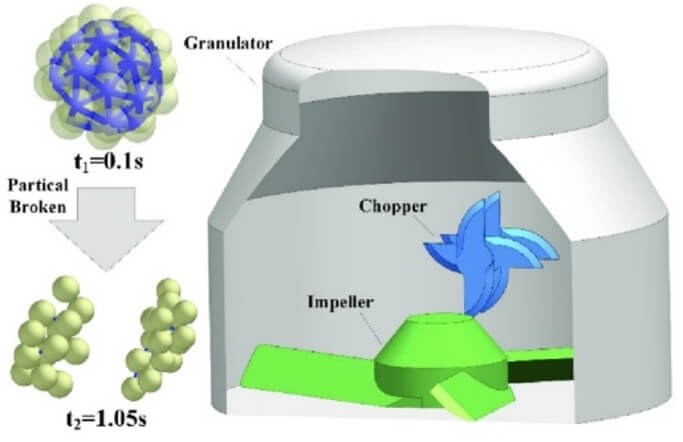

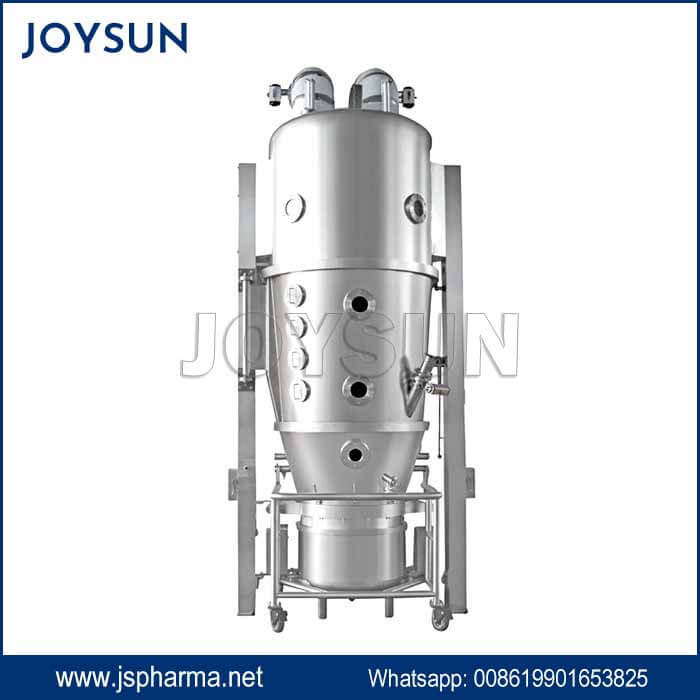

Mixing Stage

Under the action of the mixing impeller, the material undergoes various motions within the vessel, including rotation, tangential movement, and tumbling. It also rises along the vessel wall, achieving a fully fluidized state. After thorough mixing, the material forms a uniform mass.

Granulation Stage

Upon completion of the mixing, the spray gun atomizes the binder and sprays it into the vessel, allowing the binder to fully contact the material and form hollow granules.

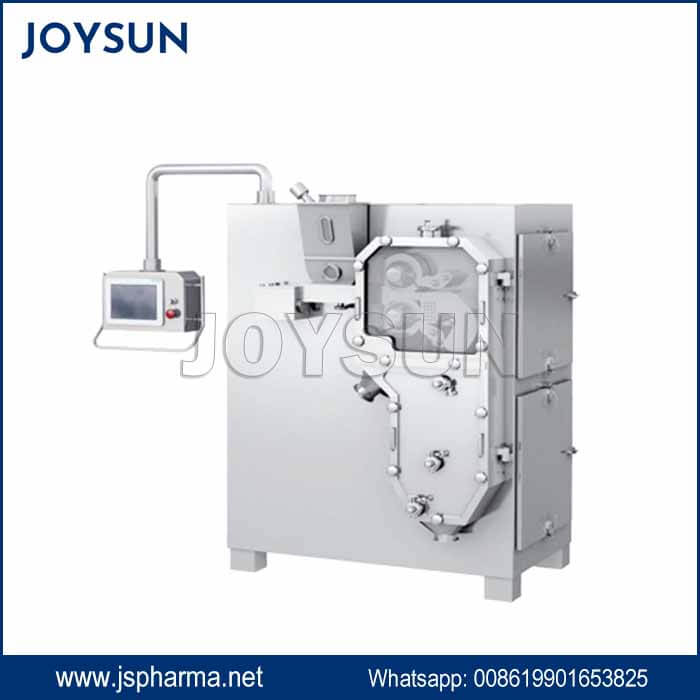

Discharging Stage

Once granulation is finished, the material is discharged from the vessel and flows into the wet granulator. After sizing and drying, the final product, consisting of uniform granules, is obtained.

In addition to these core components, a wet granulation system also include:

Control System: Monitors and regulates various process parameters such as mixing speed, liquid addition rate, and drying temperature.

Filtration System: Remove impurities or excess binder from the liquid solution before it’s added to the powder mix.

Cleaning System: Allows for easy cleaning and maintenance of the granulator equipment.

Benefits of Wet Granulation:

Improved Flowability: Loose powders can be difficult to handle and flow unevenly. Granules flow much better, making them easier to process and package.

Uniformity: Wet granulation ensures consistent granule size and distribution, which is crucial for tasks like tableting medication.

Enhanced Properties: Granules can have better binding properties compared to loose powders, making them ideal for pressing into tablets or mixing into other formulations.

Features of Wet Granulators

- Simple structure and easy operation

- Effective mixing and granulation

- Enclosed operation, preventing dust emission

- Capable of automated control

Applications of Wet Granulators

- Pharmaceutical Industry: Production of tablets, granules, capsules, etc.

- Food Industry: Preparation of solid beverages, compound food seasonings, etc.

- Chemical Industry: Synthesis of catalysts, pigments, pesticides, etc.