Description

Vibro Sifter

What is a vibro sifter?

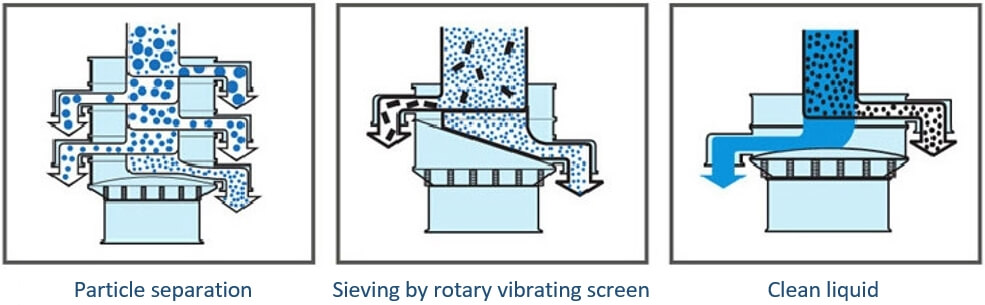

The vibro sifter, also known as a vibratory sifter, is a versatile machine used to separate materials based on sizes. It handles various tasks, including:

- Screening and sieving: Separating desired particles from larger ones.

- Grading: Sorting materials into different size fractions.expand_more

- (e.g., separating particles with different properties).

How does the vibro sifting screen work?

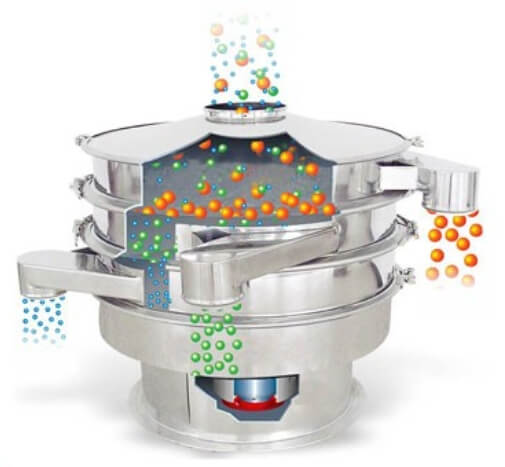

The vibro sifter utilizes a vibrating screen to achieve separation. Here’s a breakdown of its operation:

- The Machine: The core component is a screen mounted on a base plate connected to a motor.

- Feeding the Material: The material to be separated is fed through an inlet at the top and falls onto the screen.

- Separation by Size: Particles smaller than the screen mesh size pass through, while larger ones remain on top.

- Discharge: Smaller particles exit through the screen, and larger ones are discharged through a separate outlet.

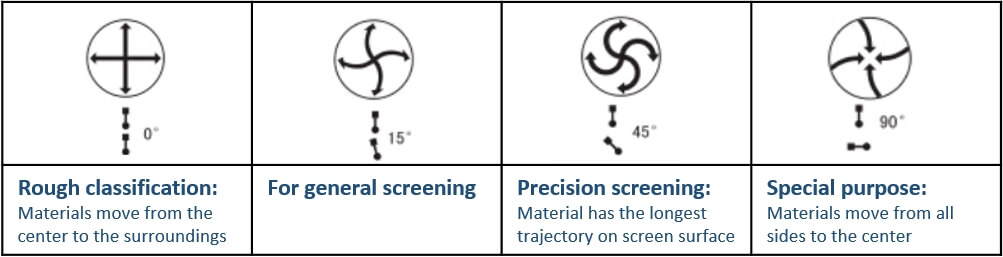

- Vibration for Efficiency: The gyratory motor and strategically placed weights create vibration, optimizing the filtration and separation process.

- Isolated Operation: The entire assembly is mounted on springs, ensuring vibration stays within the machine and doesn’t affect its surroundings.

Vibratory Sifter Key Features

- Meets cGMP Standards: Designed to comply with current Good Manufacturing Practices for quality control.

- Durable Materials: Contact parts are made from high-grade stainless steel (AISI 316) for longevity, while non-contact parts utilize AISI 304 stainless steel.

- Effective Separation: Powerful gyratory motion from the motor ensures efficient particle separation.

- Multiple Discharge Options: Offers both side outlet and discharge for finer materials.

- User-Friendly Design: Easy to move and clean, promoting efficient operation.

- Quiet Operation: Minimizes noise disruption in the workplace.

- Safety Measures: Lead-free and silicon seal sieves prioritize safety and hygiene.

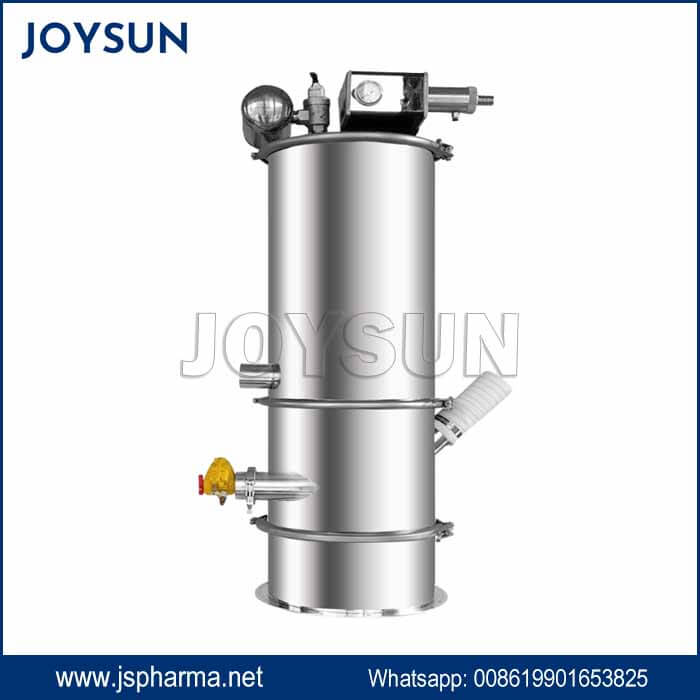

- Inline Integration:Allows for loading directly into the sifting process and transferring separated materials to bins or blenders using a vacuum transfer system. The vibro sifter is able to connected with dry powder roller compactor to sieve the milled granule, the disqualified large granule is recycled back into compacting chamber for continuous process. The process is cycled till majority of granule is satisfied to afterwards process.

For the sieve mesh is customizable upon user’s requirement. 16-100mesh. In industrial production, this sifter often uses together with powder vacuum loader; and it sometimes need ultrasonic generator to help with better flow of granule if the size is very small and high humidity.

The vibro sifter finds application in a wide range of industries due to its ability to precisely separate materials, such as

- Pharmaceutical

- Chemical

- Cosmetic

- Plastics

- Paints

- Minerals

- Rubber

- Metal Powders

- Detergents

- Pesticides & Fertilizers

- Dye stuff & Pigments