Description

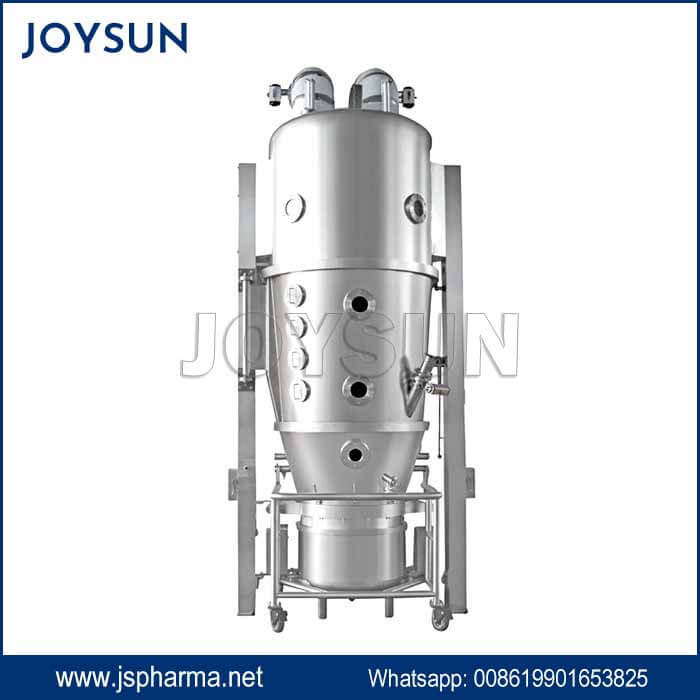

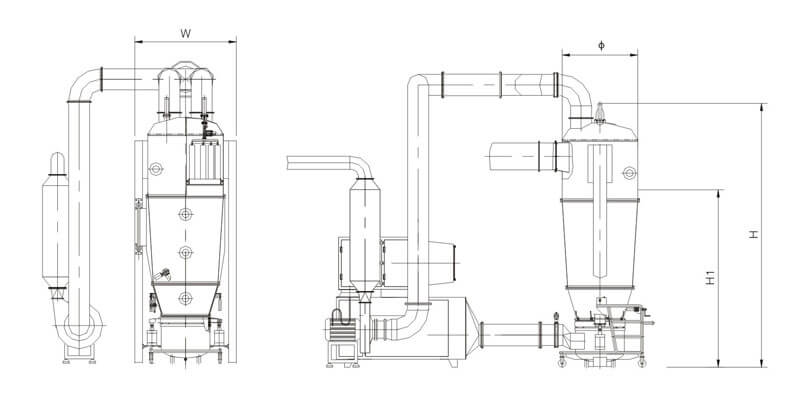

Fluidized Granulation Dryer Introduction

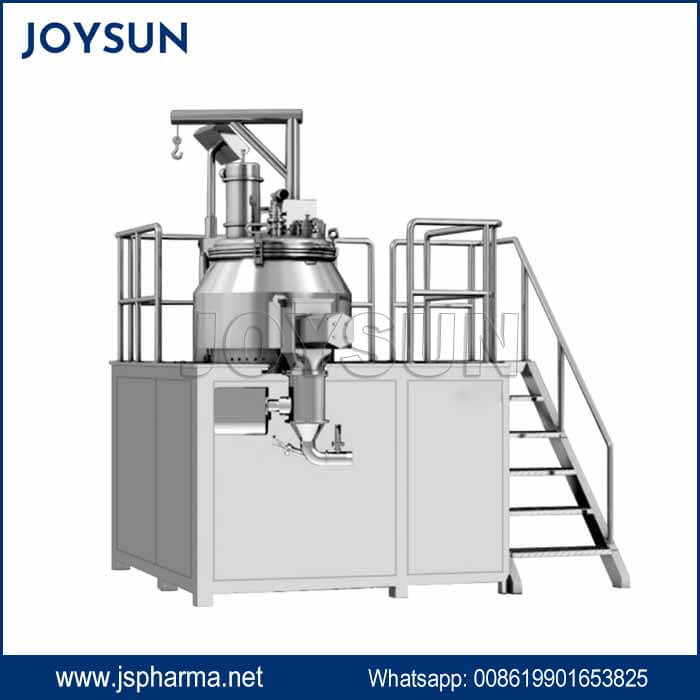

A fluidized granulation dryer is a type of equipment used to dry wet granules produced during a wet granulation process. Here’s a breakdown of how it works and how it integrates with wet granulation:

1. Feeding

The fluid bed granulation dryer utilizes the negative pressure it generates to transport wet particles from the wet granulator into the feeding chamber. The specific steps are as follows:

- Open the feeding chamber inlet valve.

- The wet granulator conveys the wet particles to the feeding chamber of the fluidized granulation dryer through the conveying pipeline.

- The negative pressure generated by the fluid bed granulation dryer draws the wet particles into the feeding chamber.

- Once feeding is complete, close the feeding chamber inlet valve.

2. Drying

After feeding is complete, the feeding valve is closed and drying begins. The specific steps are as follows:

- Start the blower to deliver hot air that has been passed through primary filtration, medium filtration, a heat exchanger, and high-efficiency filtration to the bottom of the feeding chamber.

- The hot air fluidizes the wet particles in the feeding chamber, creating a suspended state.

- The inlet temperature is adjusted by a proportional regulating valve to achieve cold-hot air compensation, ensuring that the material is dried at the optimal temperature.

- In the fluidized state, the material is fully exposed to the hot air, and moisture evaporates and is carried away with the hot air.

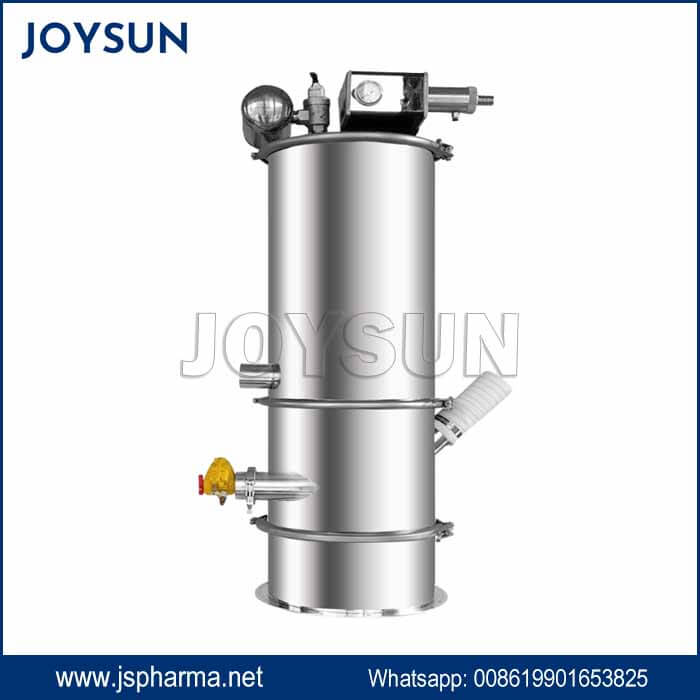

- The dust bags in the chamber are shaken according to a set program to prevent clogging.

- When the dust bags are shaken, the exhaust valve is closed to prevent the material from being discharged with the dust bags.

- The air that has passed through the fluidization chamber is extracted by the blower through the exhaust duct and enters the factory’s exhaust duct after passing through the silencer.

3. Discharging

Once drying is complete, the machine stops working and the discharging operation is performed. The specific steps are as follows:

- Open the feeding chamber discharge valve.

- The dried particles are discharged from the feeding chamber through the discharge pipeline.

- Collect the dried particles and perform subsequent processing.

- Close the feeding chamber discharge valve.

4. Finishing and Transfer

The dried particles are transferred and dry-finished using a fixed elevating feeder. The specific steps are as follows:

- Collect the dried particles from the feeding chamber into a hopper.

- Start the fixed elevating feeder to lift the particles in the hopper to a designated position.

- Transfer the particles to the next process for use.

Fluidized Granulation Dryer Summary

The working principle of the fluid bed dryer mainly includes the following steps:

- Feeding: Wet particles are transported to the feeding chamber using negative pressure.

- Drying: The material is fluidized by hot air and undergoes heat exchange with the hot air, causing moisture to evaporate.

- Discharging: The dried particles are discharged from the feeding chamber.

- Finishing and Transfer: The dried particles are collected and transferred.

Fluid bed dryers offer advantages such as:

- Fast drying speed

- Uniform drying effect

- Low energy consumption

- Wide range of material compatibility

These advantages make fluid bed dryers widely used in the pharmaceutical, chemical, food, and other industries.

Additional Notes

- The negative pressure system employed by the fluidized granulation dryer eliminates the need for mechanical conveyors and reduces the risk of material degradation.

- The hot air used for drying is precisely controlled to ensure optimal drying conditions and prevent thermal damage to the material.

- The dust bags in the fluidization chamber capture any entrained particles, ensuring that the discharged air is clean and meets environmental regulations.

The fluid bed granulation dryer is a versatile drying technology suitable for a wide range of materials, including powders, granules, and flakes.