Description

Rotary Tablet Press Machine and Tablet Pressing Machine

1. What is a Tablet Pressing Machine?

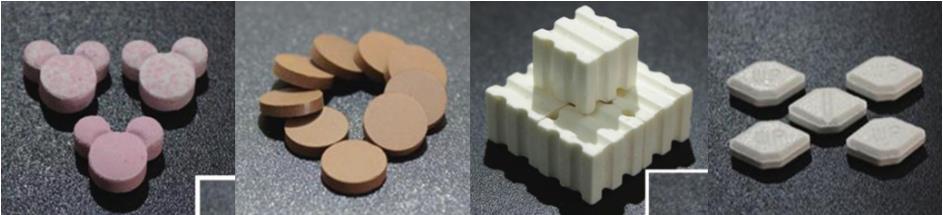

A tablet press(also known as a tablet pressing machine) is a mechanical device that works to compressing powder or granule into tablets and pills. The tablet pressing machine can produce tablets of various materials, including pharmaceuticals, nutraceuticals, cleaning products, industrial pellets, and cosmetics. To form a tablet, the granulated powder must be measured into a cavity formed by two punches and a die, and then the punches must be pressed together with great force to compress the powder together.

There are 2 types of tablet presses: single-punch and rotary tablet presses. We will focus on the rotary tablet press machine which most high-speed tablet making is using.

A rotary tablet press machine is a mechanical device that has several or multiple tooling stations that rotate to force granules/powder mixture into forms of tablets and pills. Size, shape, and weight depend on the punch design. The rotary tablet compression machine was developed to increase the output of tablets magnificently.

Advantages of Rotary Tablet Press Machine:

➢High capacity is possible using multiple stations and with a minimal amount of labor.

➢The output from 9000 to millions of tablets/hour meets mass production purposes.

➢Rotary press reduces the wastage of formulation, thus saving production costs.

➢The compression cavity is controlled automatically. Ease the operation.

➢The weight and hardness of tablets are controlled by the machine during compression.

2. The Rotary Tablet Press Machine that Joysun Has?

We have many types, series, and models of rotary tablet pressing machines to satisfy the production need. There are mainly three series as a basic model, upgrade basic models and advanced high-speed models. And among them, the difference lays in pressing speed, automation level and interaction with the MES system.

Speed: from 1,0000pcs per hour to 1,500,000pcs per hour from single punch pressing machine to multiple station rotary press machine.

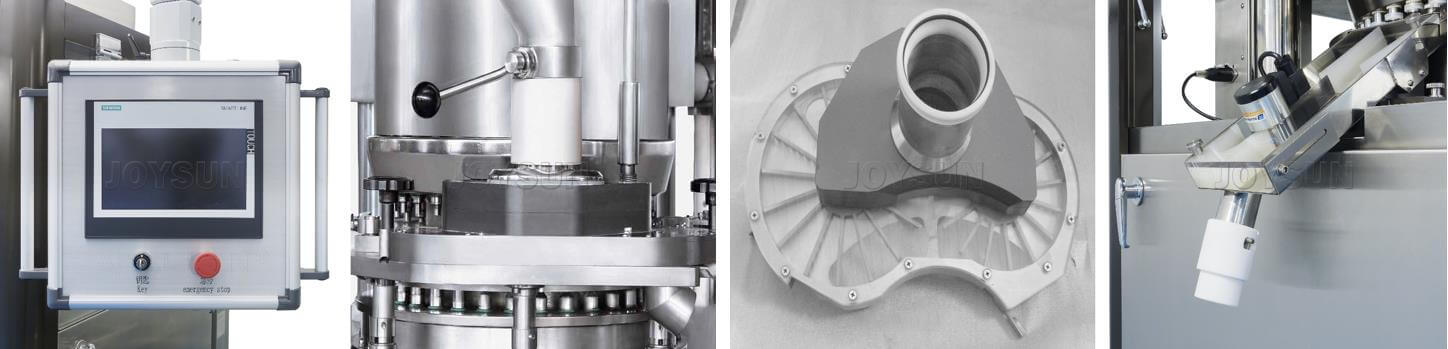

Control level: the basic one as a button, switch operation panel, upgrade type as touch screen type installed within the machine, and advanced type as separated electric control cabinet and operation station with more controlling points in PLC and can be interactive with user’s pharma management system.

3. What Industries and Applications use our Rotary Tablet Press Machine?

Pharmaceutical& Nutraceutical Applications: pills, vitamin tablets, and all kinds of medicine commonly seen in drugstore.

Food& Confectionery Applications: such as mini pill candy pill, milk tablet, mint pill, bilayer tablet, effervescent tablet and etc.

Electronic & Chemical Industries: like dishwashing tablets, detergent tablets and etc.

Basic Features of our Rotary Tablet Press Machine

1. Peripheral casing is a closed-form which is made of all stainless steel, internal mesa adopts stainless steel material, it can keep the surface glossy and prevent cross-contamination and meet GMP requirement.

2. With an oil seal ring on punches prevent oil from pollution tablet and powder leakage.

3. With a dust seal ring on punches, avoid powder leakage from the turret table.

4. Rotary Tablet Press is equipped with a variable frequency speed control device for electrical control, convenient operation, steady running, it is safe and accurate.

5. It is equipped with an overload protection device, when pressure overload, it can stop automatically.

6. Improved thicker upper pressing wheel to increase pressure 100kn to 120kn for stable production.

7. Being the leader in trying to use a semi-automatic lubrication device and the top of the rotary table is equipped with an organic glass dust prevention device.

8.Mould length from 115 to 113.6mm, improve abrasion resistance and guidance quality.

9. It is equipped with a powder absorbing device, can absorb indoor dust.

Joysun Rotary Tablet Press Demo Video

Main Crafting Material of our Automatic Pill Press

Whether an automatic pill press is strong and durable running stably for a long period of time, its manufacturing material matters greatly. Below listed the main material and hardness treatment during machine crafting.

Manufacture Material Standard and Quality

Turret table:

QT500-7 made of cast iron standard configuration, 245# hard searing-iron on the surface, SS304 stainless steel central disc

Spigot shaft and transmission shaft

GB/T3077-1999 stated 40Cr medium carbon steel structural iron

The turbine of the main transmission

GB/T1176-1987 stated ZQSn10-1 tin bronze

Worm’s turbine

GB/T3077-1999stated 40Cr medium carbon steel structure

Clamping roller

GB/T1222-1984 stated GCr15 high carbon ferro-chrome

Guideway

GB/T1222-1984 stated GCr15high carbon ferro-chrome

Batch charger

Tin bronze ZQSn6-6-3, searing-iron on the surface

Middle board

More than GB9439-1998 stated cast iron of HT200

Main material

More than GB9439-1998 stated cast iron of HT200

Chute Faceplate mask Clanying roller mask: Stainless steel (OCr18Ni9)

Our CNC machines use the latest CAD/CAM technique and advanced heat treatment process to made various kinds of punches and dies. Each tooling is precisely measured and made of fine alloy steel. With dozens of years of experiences, we can customize and provide all kinds of punches and dies such as round, irregular, shallow concave, deep concave, bevel edged, detachable, single tipped, bilayer, multi tipped, chrome plated and carbide ones. Joysun cannot only provide punches and dies to our rotary tablet pill press machine but also to special made for other brands tablet machines.

Standards of Punches and Dies for Rotary Tablet Machines

There can be 4 standards

1. International standard P/D: our high speed and ultra-high-speed series rotary tablet press use the same punch and die like brands of KORCH, FETTE, HORN, MANESTY, STOCHK, KIKUSUI and HATA Tablet Press.

2. Chinese Normal P/D for ZP: For low speed and some medium speed machine, we use Chinese standard tablet press tooling. It doesn’t mean the standard is inferior. Only it will be easier to interchange and in accordance with most tablet press machines in the Chinese market.

3. P/D for battery Press: for special purposes

4. Special Press P/D: for special purposes

The shape, size and markings of the pills are determined by the compression machine tooling punch and die

D Tooling: most popular for large tablets: barrel diameter 1 inch (25.4mm) ;

Head Diameter 1 1/4 inch; Length-5.25 inch(), Dies outer diameter-0.945 inch.

BB Tooling: most common: Barrel diameter-0.75 inch;

Head Diameter-1 inch; Length-5.25 inch,

B tooling is the same as BB only difference is that the lower punch length is just 3 and 9/16th inches long.

Joysun Tablet Machine Detail

How does the Rotary Table Press Work?

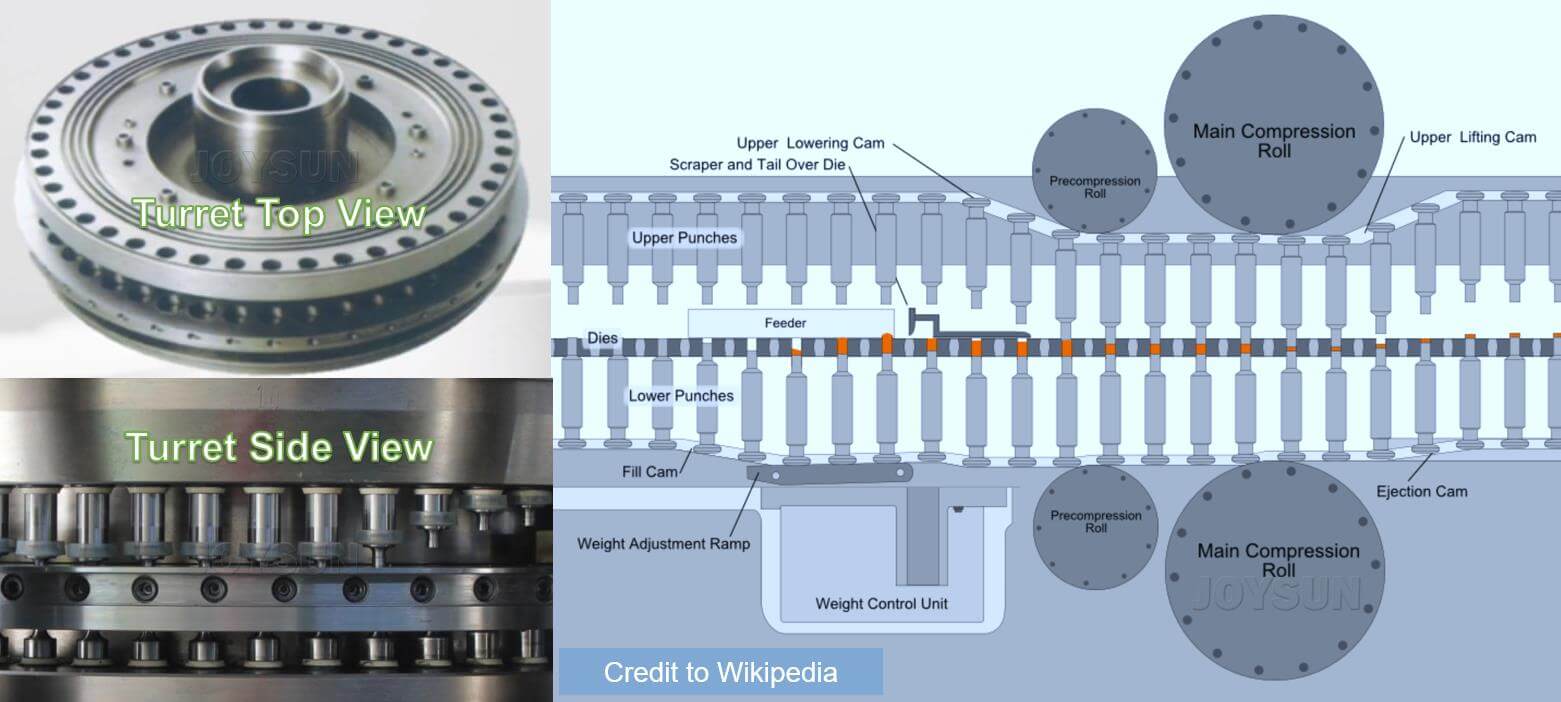

Working and Principle of Multiple Station Tablet Rotary Press

Tablet pressing steps can be divided into the following:

1) Powder/ granule filling: the material is filled and falls down through a hopper.

2) Pre-compression (in high-performance speed machines): is a step where the tablets are partially formed under the force of a pre-compression roller. At a low-speed rotary tablet press, there is only one compression roller. The pre-compression stage can also carry out deaeration action to make a more even tablet. If air stays inside the pores and particles, the capping issue may occur during the main compression process.

3) Main compression: is a stage where a higher force from the main compression roller is applied to compress and consolidate powder into tablets and pills. So the compression roller generated force is usually higher than the pre-compression roller force. At a high speed tablet press, pre-compression roller and compression roller both use at the same time to reduce the failure rate of pressing.

4) Tablet ejection: this step also requires force to break the adhesion between the die wall and compact surface and other forces needed to complete the ejection of the tablet.

5) Rejection (disqualified tablets, pills if any, optional)

6) Sampling(optional)

The turrets hold many numbers of punches. There are upper turrets and lower turrets. As turrets rotate, the upper punches also move vertically to contact the lower punches. The fast and strong contacting between punches generates high compaction force so as to form powder granule into tablet and pill dosages. The bigger diameter of the turret and more numbers of punches and dies and higher rotation speed usually mean a faster-pressing capacity.

Joysun Rotary Tablet Machine Use Conditions

There are several checking points to use our tablet press.

⚫ The particles (powder and granule) are uniform and not damp, and the particle ratio is not less than two-thirds.

⚫ Particle (powder and granule) size range: 14-60 mesh, with good compressibility and fluidity。

⚫ Operation Room with relative humidity not more than 65%; temperature not more than 35℃, and good ventilation.

⚫ Working environment or cleanroom conditions should meet GMP requirements.

⚫ The power supply should be a three-phase five-wire system, and the N wire and PE wire must not interfere with each other.

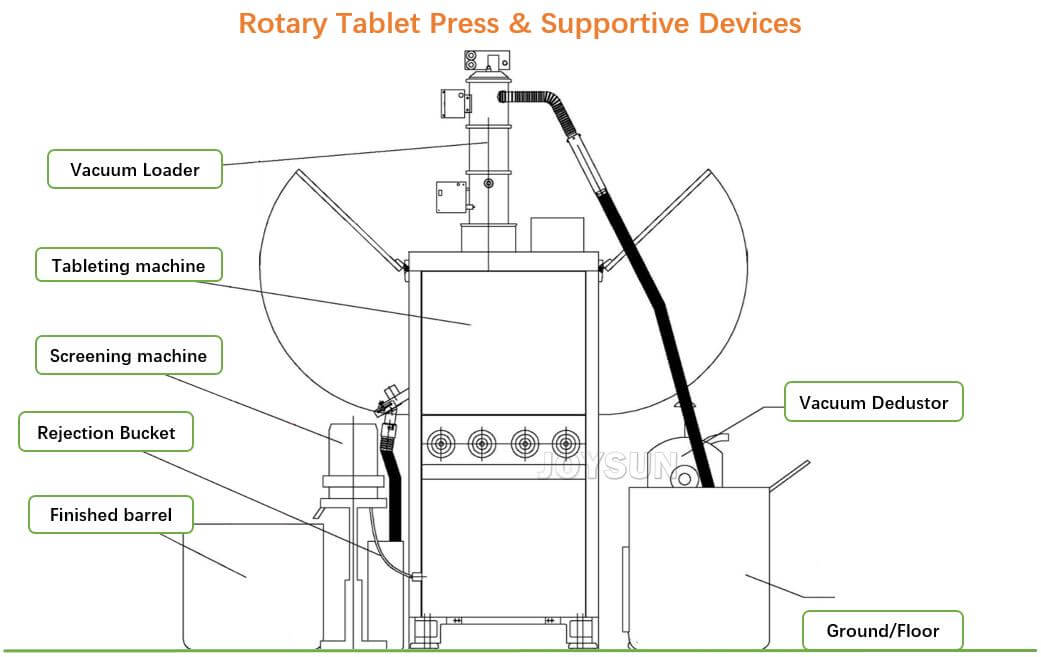

What Auxiliary Equipment to Use Alongside Rotary Tablet Compression Machine?

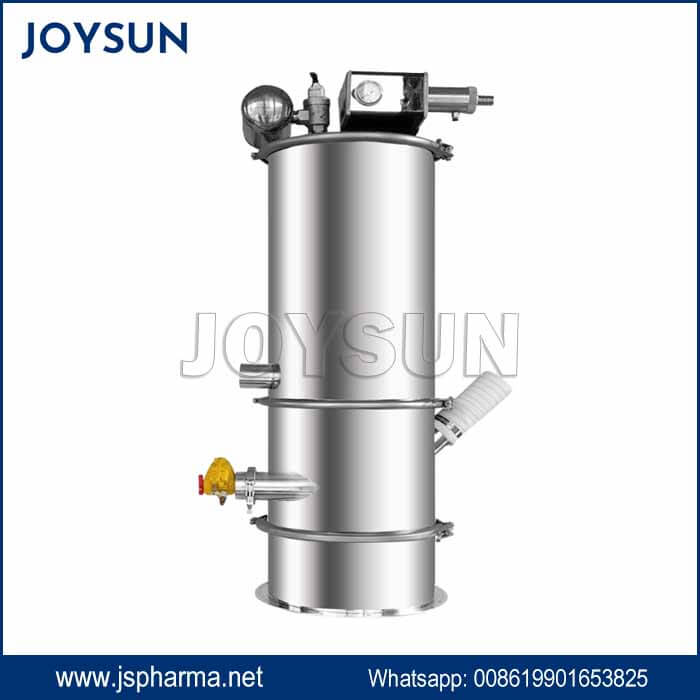

Depends on the machine model, capacity and powder property, buyers can choose to have a vacuum powder loader, vacuum deduster, tablet sorting machine. The cooperative work of that equipment makes tablet pressing more efficient.

In order to eliminate dust accumulated in the tablet pressing chamber, this machine is equipped with a vacuum deduster. It is used to eliminate dust on the punching disc, upper and lower punching rods. The dust vacuuming device can be purchase optionally and independently, Parameters are wind pressure 880Pa, wind rate 700 cubic meter/hour.

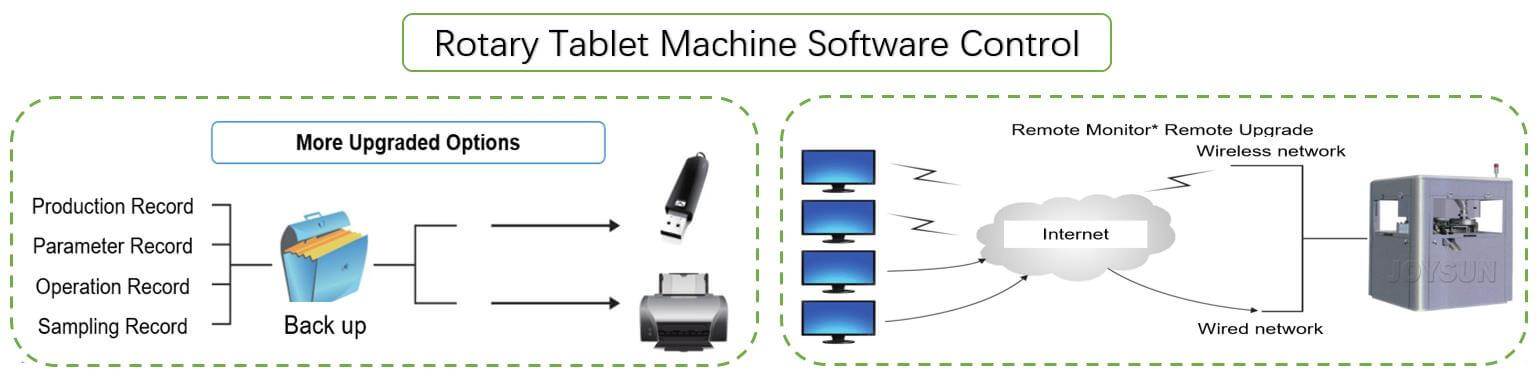

Automatic and Upgraded Electric Software Control

For full automatic tablet press, high and ultra-high speed pill press machines, we use advanced electric software control. Data backup, traceability and log. Operation control provides intuitive data display for the users. The large color touch screen makes all production data obvious. Using the special software of this machine, it is very easy to set the position of the upper and lower punches, as well as the pressure required for the main pressure and the pre-pressure.

A Brief Sample of Rotary Tablet Press URS (Reference Only)

For most pharmacy factory purchasers, they source rotary pill machine upon specified URS (shorten for User Requirements Specification), below Joysun showcase a short version of main points.

An official URS should include at least the below items:

- Tablet Compression Machine General description

- Specific requirements

- Performance Parameters:

Tablet press machine to be designed and constructed in accordance with cGMP in general line in order to convert the granules to tablet.

The working capacity shall be ***Tablet/hour;

The products range are:

Tablet size: Min: ***mm – Max: *** mm

Type of Tablet: Oval, Convex, Oblong, round and ***

Tablet Thickness: Min: ***mm – Max: *** mm

Tablet Diameter: Min: ***mm – Max: *** mm

Type of Tooling: BB / DD /D/B

Main Compaction force: Min: *** KN – Max: ***

Pre-compaction force: Min: ***KN – Max: ***

– – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

Dust tight docking system for feeding/discharging must be provided.

The processing area must be separated from the mechanical area.

Doors must be sealed.

Easy dismounting of all parts in contact with the product to reduce airborne parts to be washed out of place.

A safety system must be provided in emergency conditions like power blackouts.

Exit chute with 3 channels (good tablets, rejected tablets, sampling must be provided.

Powder hopper must be fitted perfectly to avoid airborne at feeding.

Earthlings system for the machine must be provided.

Consumable material and spare parts must be considered by the vendor.

– – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

- Rotary Tablet Press Construction Standards

All contact parts with the product in 316L stainless steel and non-contact part in 316/304 stainless steel constriction.

Surface finish: Mechanical Polished and passivated.

Surface roughness: Internal Ra≤ 0.8 (μm).

Gaskets, Seals and O-ring; FDA-approved Polymeric material only.

– – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

- Rotary Tablet Press Engineering Standards

The basic layout of the equipment is required.

The installation Layout of the equipment is required.

A list of all components including material description is required.

Total weight and capacity shall be mentioned by the manufacturer.

The construction of the complete system should be described in the documentation, in detail.

The machine shall be equipped with a phase control system.

The machine shall be provided with a complete electrical panel.

The equipment and its control panel should be flameproof and water proof (appropriate IP enclosure must be given by the vendor).

The control system shall consist of PLC & HMI (or pc).

– – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

- Rotary Tablet Press Utilities

Electricity consumption must be given by the vendor.

Motor power must be given by the vendor.

Compressed Air consumption must be given by the vendor.

Air pressure must be given by the vendor

– – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

- Rotary Tablet Press General Documentation

Certificates of origin.

Operating manual with parts specifications, testing certificates of components and certificates of traceability and other.

Transport, installation and startup.

Layout and features.

Machine setup and change over.

Technical datasheets.

Piping and Instrumentation Diagram.

General Assembly (GA) drawings.

Utility requirements.

Design specifications.

Manuals / Test Certificates of Bought out Components.

Material Test Certificates (EN – 10204 or Equivalent) for S.S. 316L contact parts.

The material of construction.

All test reports including internal test reports.

Electrical Documentation – Circuit Diagrams, Terminal Connection plan with an overview, Cable Layout Plan, Technical Data Sheets, Equipment Datasheet, Pneumatic diagram, Alarm list.

Cleaning procedure

Component list

Safety Regulation

Recommended Spare Parts List.

Validation Documents

Design Qualification (DQ)

FAT Protocols and Reports

Installation Qualification (IQ)

Operation Qualification (OQ)

Installation, Operation and maintenance manual

Documentation for the performance of qualification on-site, including verifying the operation of safety devices, traceability, and user management.

– – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

- Rotary Tablet Press Installation & Commissioning

The transport system of the machine should be smooth to avoid any damages e.g., scratches and breakage.

The supplier shall provide a QA plan on receipt of the Purchase Order. Third-party stage wise inspection may be carried out.

Protocols shall be provided by the vendor for approvals.

FAT will be conducted with pre-approved protocols.

SAT (IQ and OQ) will be conducted on-site, with pre-approved protocols.

– – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

- Tablet Compression Machine Validation

Design Qualification (DQ)

Installation Qualification (IQ)

Operation Qualification (OQ)

Documentation for the performance of qualification on-site, including verifying the operation of safety devices, traceability, and user management.

– – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

- Rotary Tablet Press Computer Hardware & Software

The control system shall store electronic records in a way which is compliant with the requirements of 21CFR part 11 for electronics records.

Software used to generate, process, store the quality critical data must be validated and must comply 21 CFR part-11. Full compliance with GAMP5 guidelines.

The HMI panel shall have four access levels as mentioned below, with different authorizations for each level:

I. Operator

II. Administrator

III. Supervisor

IV. Programmer

The system shall have all requisite password protection levels (min 3), audit trails, alarm/ event history, trends and parameters with the batch number in a secure database, etc.

– – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

- Training

- Definitions