Description

Tablet Compression Machine|Lab Use Single Punch

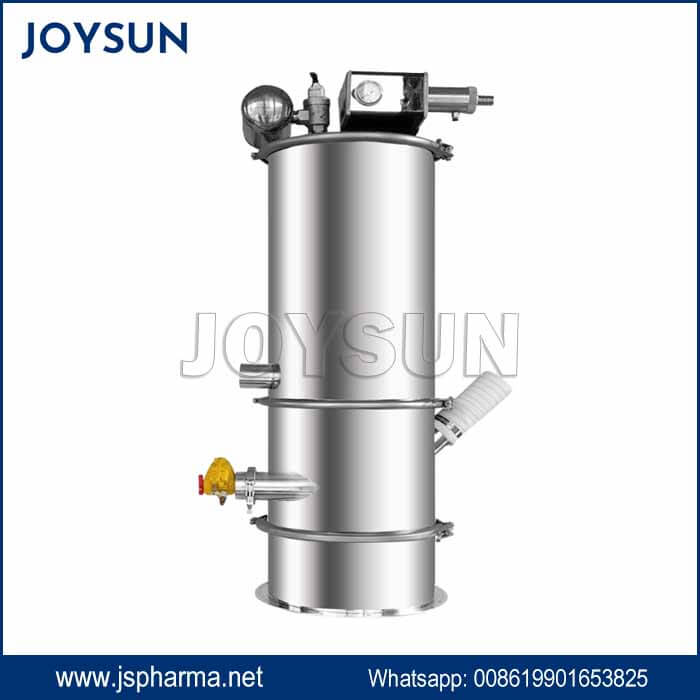

A Single Punch Tablet Press, also known as a Single Station Tablet Press or Single Station Tablet Compression Machine, is for use in tablet production in the pharmaceutical and nutraceutical industries. It is a mechanical device that compresses powdered or granulated materials into tablet form through a single pressing action.

The Single Punch Tablet Press typically consists of a stationary die and a rotating turret or wheel that holds the punches. The die has cavities of various shapes and sizes, which determine the final tablet shape and dimensions. The granulated material is fed into the die cavity, and when the punch comes into contact with the material, it compresses it, forming a tablet. The excess material is ejected, and the process repeats for the next tablet.

Compared to rotary tablet presses, which have multiple stations or tooling sets, the Single Punch Tablet Press has a simpler design and is often used for small-scale production or for research and development purposes. It offers advantages such as ease of operation, lower cost, and versatility in producing tablets of different shapes and sizes.

However, it’s important to note that the production speed of a Single Punch Tablet Press is relatively slower compared to higher-capacity machines. Therefore, for large-scale manufacturing, multi-station tablet presses are typically preferred due to their higher output and efficiency.

Parameter

| Power | 0.75kW | 1.5kW |

| Voltage | 3P/220V,380V 50Hz/60Hz | 1P/220V,380V 50Hz/60Hz |

| Capacity | 3500 pcs/h | |

| Tablet diameter | 25(Ø25) mm | |

| Filling depth | 18mm | |

| Tablet thickness | 7mm | |

| Dimension (L*W*H) | 780×450×690 mm | |

| Weight | 150 kg | |